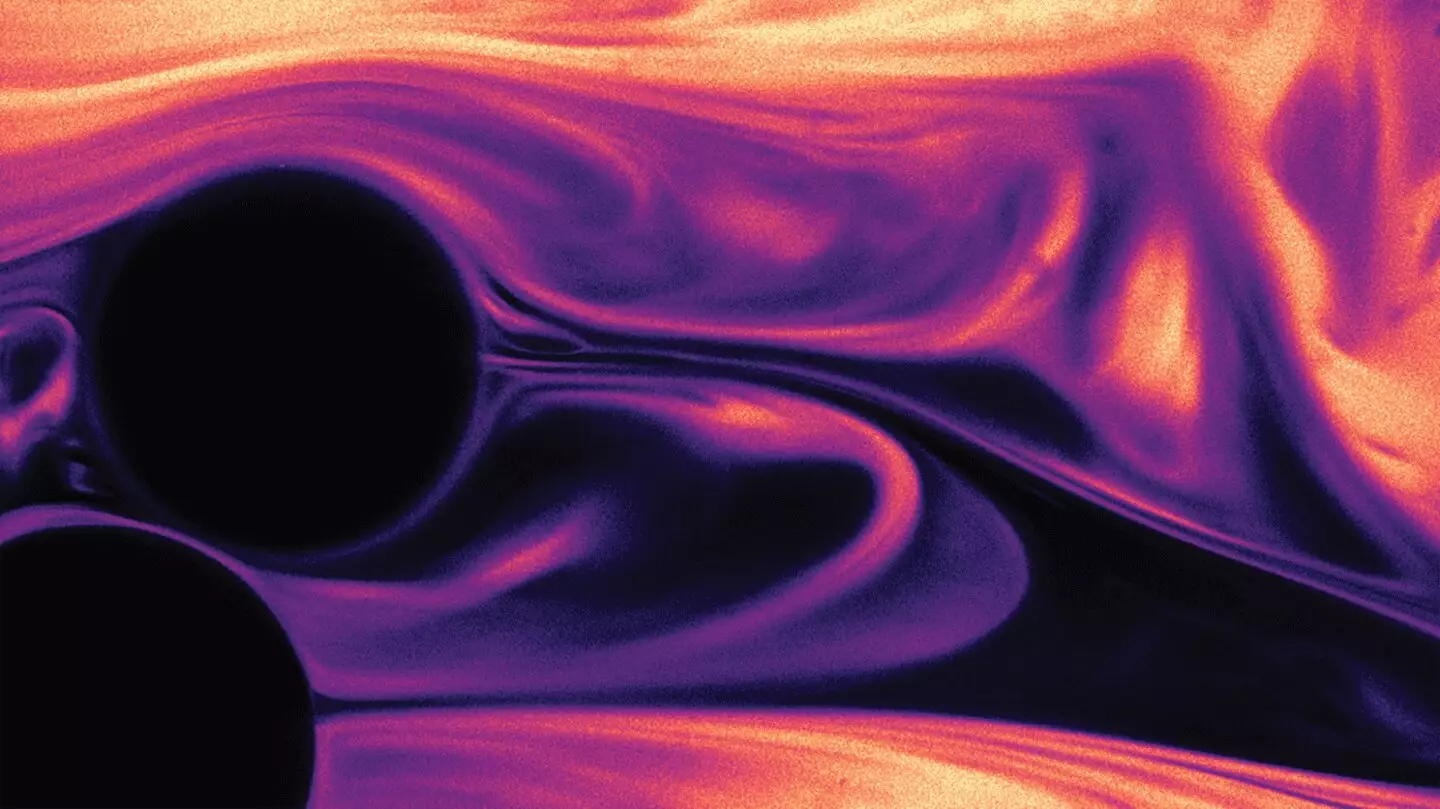

Mixing may appear to be a mundane task—an essential step in culinary endeavors such as brewing coffee or preparing a smoothie. Yet, the science and technology behind effective mixing hold immense implications for various industries, from food production to chemical engineering. Imagine witnessing the mesmerizing dance of cream swirled into coffee, creating intricate patterns that spark joy. What happens when this delicate mixing is disrupted, however? A mere stir with a spoon can obliterate that beautiful chaos and render everything into a homogenous brown, stripping it of its visual allure. But beyond the aesthetics, mixing plays a vital role in chemistry, influencing the efficiency and outcomes of countless reactions that bring life to everyday products. In the realm where science meets industry, researchers and engineers are striving to perfect this art.

The Challenge of Mixing in Porous Environments

While industrial processes often require vigorous mixing, achieving optimal fluid interactions in packed bed systems—like those utilized in carbon capture or chemical manufacturing—poses significant challenges. Here, we often encounter an unusual paradox. Unlike the swirling turmoil in a coffee mug, the tightly packed grains in an espresso machine create minute spaces, termed pores, that restrict the chaotic turbulence essential for thorough mixing. The challenge lies in the fact that these confined spaces limit the ability of fluids to interact effectively, which is crucial for driving chemical reactions to completion. The limitations imposed by these environments can have massive repercussions on production efficiency, driving the need for innovative solutions.

A Revolutionary Discovery: The Role of Springy Polymers

In an exciting advancement, researchers from Princeton Engineering have unlocked the secret to enhancing mixing within these challenging porous realms. By introducing elastic polymers into one of the liquid phases, they managed to mimic the turbulent mixing experienced in broader volumes like coffee mugs. The concept is simple yet profound: these springy polymers, equipped with the ability to stretch and recoil at microscopic levels, serve to transform each pore into a dynamic mixing chamber. When applied correctly, this technique can facilitate fluid interactions akin to those found in more spacious environments, providing a significant boost to overall reaction rates. According to research led by Christopher Browne, a graduate alumnus, and his adviser Sujit Datta, the method has demonstrated the potential to expedite chemical reactions by as much as tenfold, transforming the landscape of chemical production.

The Journey of Discovery: Overcoming Hurdles

Browne’s research journey began in his early days at Princeton, where he aimed to tackle the intricate challenges posed by mixing phenomena. This undertaking was not devoid of hurdles; from evaluating the impacts of polymers on liquid dynamics to fine-tuning complex fluids for predictable behaviors, the path was laden with complexities. Just as one unravels a tangled thread, Browne had to navigate through a myriad of related problems before arriving at his groundbreaking findings. His unwavering dedication ultimately culminated in a fascinating body of work, rich with insights that push the boundaries of what was previously thought possible.

Real-World Applications: From Theory to Practice

Perhaps most exciting, though, is the broad applicability of these findings. The polymers Browne and Datta utilized are not exotic materials; they are chemically akin to the absorbent materials found in everyday items like diapers. This finding opens the doors for a diverse range of materials to be employed in similar capacities, allowing for customization based on specific industrial needs. By circumventing archaic methods of modifying the geometry of packed beds—which often proves costly and impractical—the researchers present a robust, cost-effective solution that can adapt to various porous environments in real-world applications.

Aesthetic and Practical: The Beauty of Fluid Dynamics

While engineers and scientists have long sought to fashion practical solutions from fluid dynamics principles, Browne and Datta have successfully combined the pursuit of knowledge with real-world impacts. Their work not only demonstrates the complexity at play in mixing but also reflects the beauty inherent in these phenomena. As Datta aptly put it, the elegance of their method lies in its potential to catalyze substantive advancements in chemical production efficiency. Every swirl and dance of polymers within those confined spaces now represents a transformative approach potentially reshaping industrial practices for years to come.

Leave a Reply