The landscape of transportation is undergoing a dramatic shift, largely driven by the need for sustainable and efficient energy solutions. Central to this transition is the development of electric vehicles (EVs), which rely heavily on cutting-edge battery technology to enhance their performance and usability. The quest for improved battery systems has led to the exploration of structural batteries—an innovative approach that not only facilitates energy storage but also contributes to the physical structure of electric vehicles. This article delves into recent advancements in this field and the promising implications for the automotive industry and beyond.

Structural batteries differ from traditional batteries by integrating energy storage capabilities directly into the vehicle’s framework. Instead of merely being components that are affixed to a structure, these batteries are designed to function as both energy reservoirs and load-bearing elements. This dual functionality significantly optimizes space and material use, a crucial factor in enhancing the performance of electric vehicles, which tend to be limited by weight and volume constraints. Researchers have recently made strides in creating these innovative batteries using methods such as 3D printing, which allows for flexible designs tailored to specific applications.

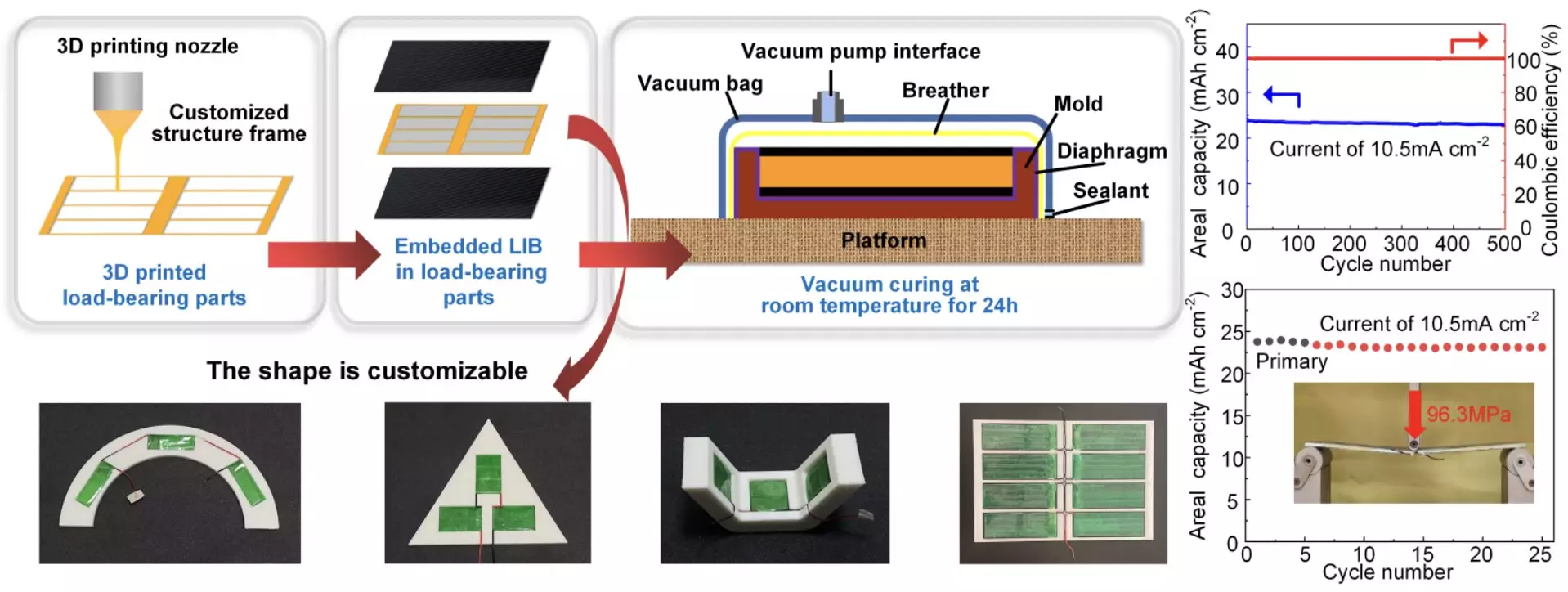

At the forefront of this research, scientists at Shanghai University have developed a strategy for manufacturing structural lithium-ion batteries with customizable geometric configurations. This approach not only caters to energy density but also ensures high mechanical stability. The implications of such technology can extend beyond electric vehicles, catering to a variety of applications, including robotics and logistics systems.

One of the standout aspects of this research is the use of 3D printing to fabricate batteries. This method opens a world of possibilities, allowing for the creation of intricate patterns that can meet the unique requirements of various structures. One of the primary advantages of using 3D printing is its ability to produce components with precise geometrical configurations that can enhance the structural integrity of the battery while minimizing damage during operation.

The strategy focuses on two main components: the energy storage unit and the structural framework. By employing a decoupled design, researchers aim to reduce the deformation experienced by the energy unit during load, thereby improving mechanical stability and overall performance. This innovative approach indicates a significant departure from traditional battery designs that often face challenges like low energy density and mechanical reliability issues.

In preliminary tests, the fabricated structural batteries showed impressive resilience under various stress conditions, sustaining both tensile and bending stress while maintaining a remarkable energy density of 120 Wh kg^-1. Such performance metrics underscore the potential of 3D-printed structural batteries to compete with, and in some cases, exceed the performance of conventional battery systems.

One particularly notable finding was that the composite structural battery retained 92% of its capacity after 500 cycles of operation—a testament to its durability and longevity. This kind of performance is essential for practical applications in the electric vehicle market, where both efficiency and reliability are critical. Moreover, the versatility of the design means that it can be tailored for different operational needs, signaling a potential revolution in how energy storage is approached across industries.

The future of structural batteries appears bright, with researchers anticipating applications extending into various fields beyond electric vehicles. The technology holds promise for the development of energy storage solutions in unmanned aerial vehicles (UAVs) and autonomous robots, further broadening the horizon for energy integration across sectors.

By optimizing materials and employing advanced simulations, the path towards practical, high-capacity structural batteries is becoming clearer. Researchers envision a future where these batteries can undergo large-scale production, providing energy-efficient solutions tailored to specific applications while remaining robust and reliable under stress.

As the research progresses, the implications of such innovations could redefine the standards for battery efficiency and structural integrity, ushering in a new era characterized by smarter, lighter, and more sustainable energy solutions for transportation and automation.

The advancement of structural batteries represents a critical step in overcoming the current limitations faced by battery technologies. By leveraging innovative fabrication methods and strategic design principles, researchers are paving the way for a more sustainable and efficient future in energy storage and utilization across various industries.

Leave a Reply