3D printing technology has revolutionized the construction industry, offering quick and precise construction with the possibility of using recycled materials. However, questions about the sustainability and durability of 3D-printed structures have remained. One potential solution to these challenges is the incorporation of cellulose nanofibrils, a plant-based material, into printable materials.

Cellulose nanofibrils, derived from wood pulp, offer a renewable and low-impact alternative for enhancing the properties of 3D-printed concrete. These nanofibrils have shown strong potential in improving the flow properties and mechanical strength of composite materials. The use of cellulose nanofibrils could lead to more resilient and eco-friendly construction practices in the future.

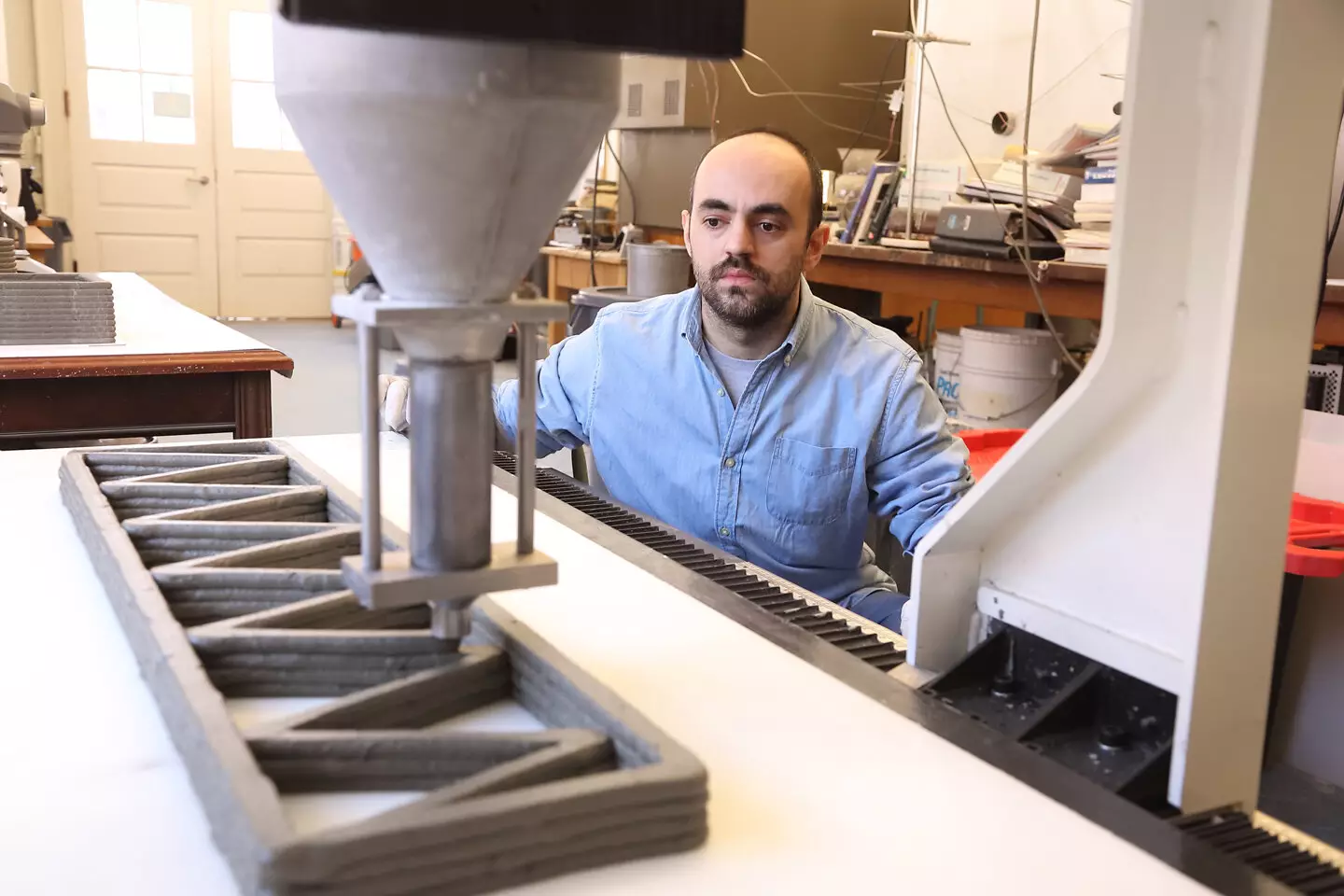

A research team led by engineers at the University of Virginia School of Engineering and Applied Science conducted a study to evaluate the effects of cellulose nanofibrils on 3D-printed concrete. The team found that adding at least 0.3% of cellulose nanofibrils significantly improved the flow performance of the material. Microscopic analysis of the hardened samples revealed better material bonding and structural integrity.

The incorporation of cellulose nanofibrils in 3D-printed concrete could address the contradictory objectives faced by designers and builders. By enhancing the rheology and mechanical strength of composites, cellulose nanofibrils offer a promising solution for creating more sustainable and durable structures. Additionally, the use of plant-based materials like cellulose nanofibrils aligns with the growing emphasis on eco-friendly construction practices.

Moving forward, more research is needed to fully understand the potential of cellulose nanofibrils in enhancing 3D-printed concrete technology. By conducting further experiments and studies, researchers can optimize the use of cellulose nanofibrils and explore their broader applications in construction. The findings of this research pave the way for more innovative and eco-friendly building practices in the future.

The research conducted by the University of Virginia School of Engineering and Applied Science highlights the significant impact of cellulose nanofibrils on 3D-printed concrete technology. By improving the flow properties and mechanical strength of composite materials, cellulose nanofibrils offer a promising solution for creating more resilient and sustainable structures. As the construction industry continues to embrace 3D printing technology, the integration of plant-based materials like cellulose nanofibrils could lead to a more environmentally friendly approach to building design and construction.

Leave a Reply