Innovations in water treatment technology are constantly evolving, with engineers and researchers striving to find efficient and sustainable solutions to address the presence of harmful chemicals in our water supply. One such groundbreaking development comes from the University of Bath, where a team of researchers has devised a method using 3D printing to remove ‘forever chemicals’ from water.

Perfluoroalkyl and polyfluoroalkyl substances (PFAS) are commonly referred to as ‘forever chemicals’ due to their persistent nature in the environment, taking over 1,000 years to break down. These man-made chemicals, such as perfluorooctanoic acid (PFOA), have been linked to a range of health issues, including reproductive and developmental harms, cardiovascular effects, and an increased risk of diabetes. Sources of PFAS include everyday products like non-stick pans, raincoats, fabrics, and firefighting foams.

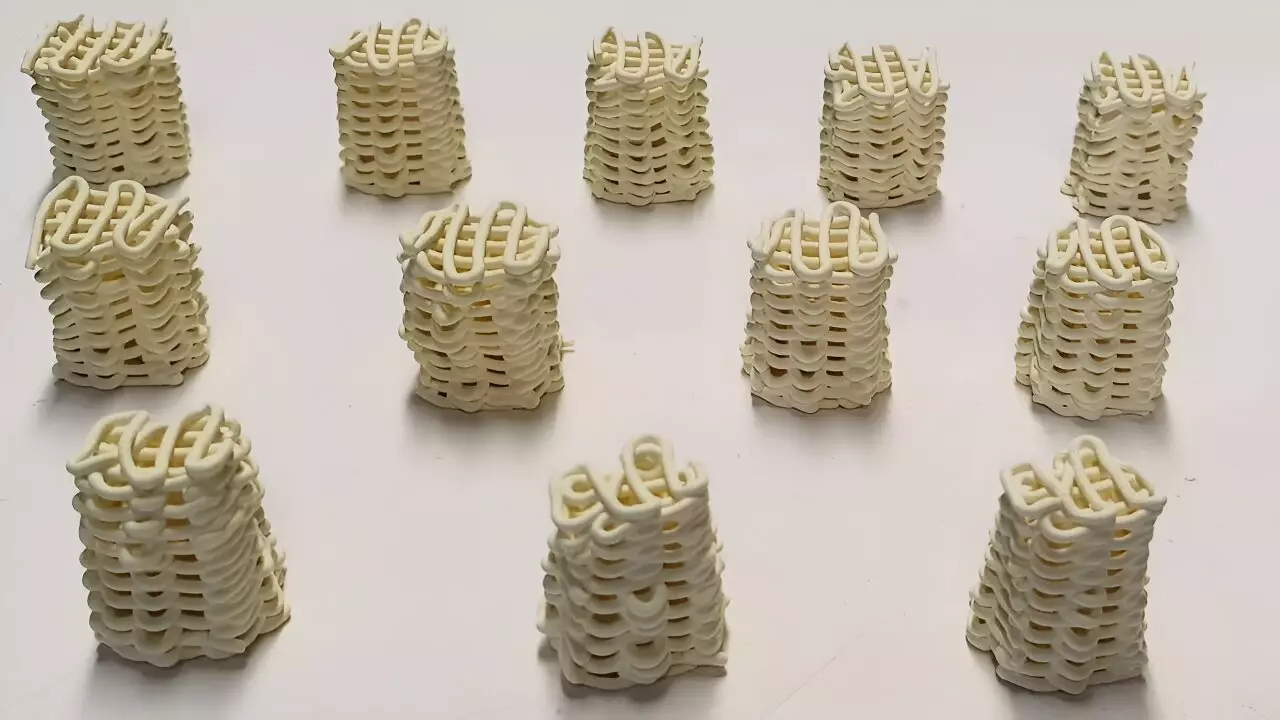

Using ceramic-infused lattices, also known as ‘monoliths,’ created through 3D printing, researchers at the University of Bath have achieved a significant milestone in removing PFAS from water. This method has shown to eliminate at least 75% of PFOA from water, offering a promising solution to combat the detrimental effects of these chemicals on public health and the environment.

The use of 3D printing technology in creating these monoliths presents several advantages. The high surface area of the printed objects enhances their efficiency in capturing and removing PFAS from water. Moreover, the scalability of the 3D printing process makes it a practical and cost-effective solution for widespread implementation in water treatment facilities.

While regulations on acceptable levels of PFAS in drinking water are already in place in some regions, such as the US and EU, further legislative actions are expected as the awareness of the health risks associated with these chemicals grows. In the UK, where regulations on PFAS in drinking water are not yet stringent, water companies may soon adopt innovative systems like the ceramic monoliths developed by the University of Bath researchers.

The research team is continuously working to enhance the efficiency of the ceramic monoliths in removing PFAS from water. Initial tests have shown promising results, with the monoliths proving to be more effective after repeated use and undergoing thermal treatment for regeneration. The researchers are committed to further experimentation to optimize the performance of the monoliths and gain a deeper understanding of their long-term effectiveness.

The integration of 3D printing technology in water treatment processes marks a significant advancement in the fight against harmful chemicals contaminating our water supply. The innovative approach developed by the University of Bath researchers showcases the potential for sustainable and effective solutions to safeguard public health and environmental safety. As we strive to create a cleaner and healthier future, the use of 3D printing in water treatment holds great promise in addressing the challenges posed by ‘forever chemicals’ like PFAS.

Leave a Reply