Polyurethane (PUR) foam is an incredibly versatile material that is used in a wide range of products, from mattresses to insulation in refrigerators and buildings, to shoes, cars, airplanes, wind turbine blades, and cables. While PUR is incredibly useful, its disposal poses a significant environmental and climate burden. Most PUR products end up being incinerated or dumped in landfills, despite the fact that the main components of the material are primarily derived from fossil oil. With the global market for PUR expected to reach nearly 31.3 million tons by 2030, finding a way to recycle and reuse PUR foam is crucial for reducing waste and minimizing the use of virgin materials.

While there is a small but growing industry focused on chemically breaking down PUR foam into its original components, polyol, and isocyanate, the process is expensive and inefficient. Separating and purifying the desired elements is a major challenge, making it difficult for recycled materials to compete with virgin materials. Additionally, manufacturers in the PUR industry use unique formulae to achieve specific material properties, creating further complications in the recycling process. Waste sorting, logistics, and sorting PUR into different types all present significant obstacles to creating a truly circular economy for polyurethane.

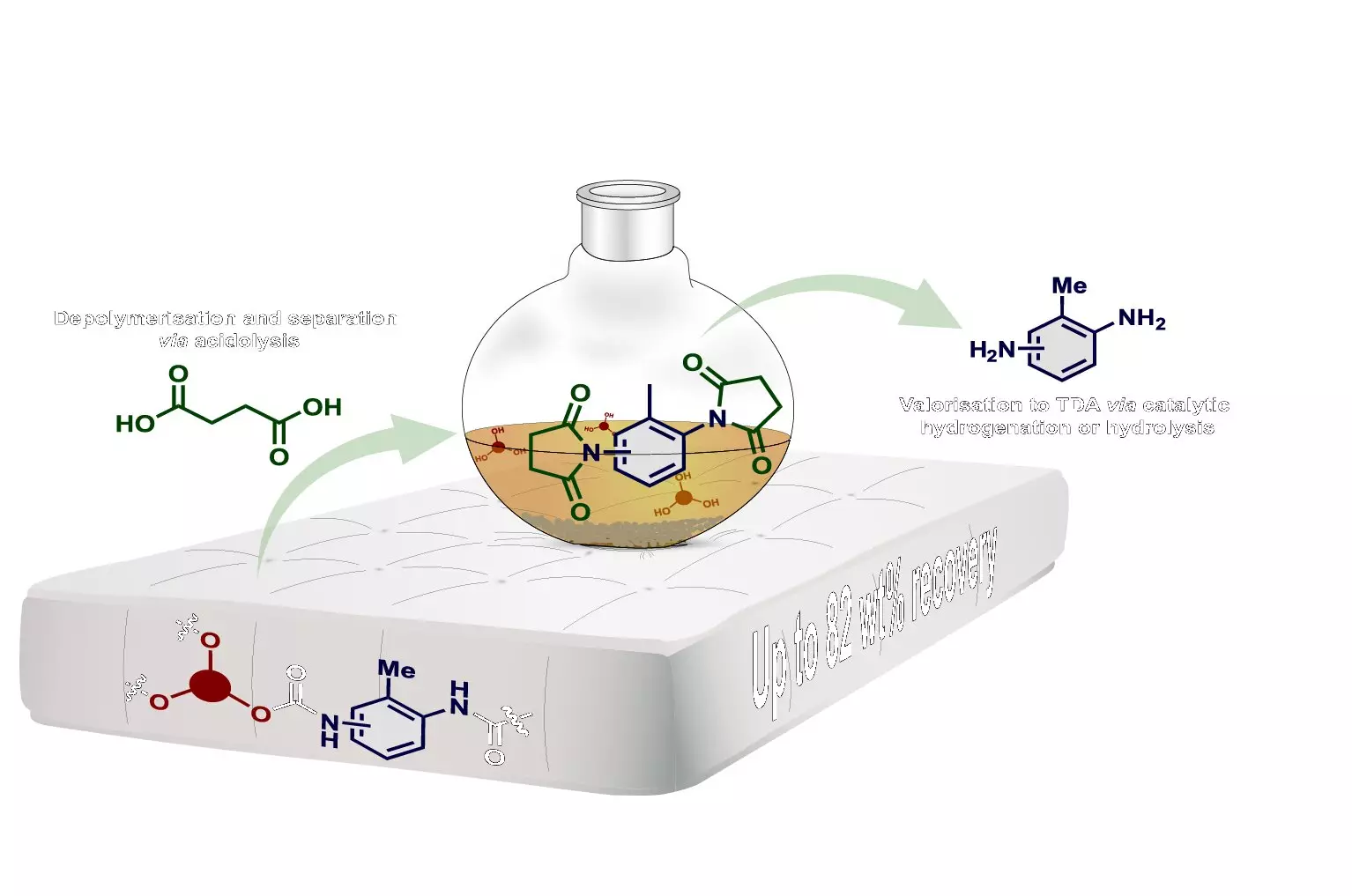

Researchers at Aarhus University have recently developed a groundbreaking method for recycling polyurethane foam that promises to revolutionize the industry. By combining acidolysis and hydrolysis, the researchers are able to break down flexible PUR foam into its main components, polyol, and isocyanate, in a single step. By heating the foam to 220°C with succinic acid and using a specially designed filter, the researchers are able to separate and purify the polyols, creating a product that is comparable in quality to virgin polyol. The remaining solid material is transformed into a diamine, which is used in the production of isocyanates and, ultimately, new PUR products. This innovative process allows for the recovery of up to 82% of the original material from flexible PUR foam, significantly reducing waste and the need for virgin materials.

The researchers at Aarhus University are optimistic about the potential of their recycling method to transform the industry. They see opportunities to scale up the process for use in factories that produce PUR foam products, such as mattresses. However, challenges remain in handling PUR waste from consumers due to the unique formulae used by manufacturers. The researchers are continuing to explore the use of their method on other types of polyurethane materials and are investigating ways to reuse dicarboxylic acid in the process. By testing recycled materials and creating new products, the researchers hope to demonstrate the viability of their technology in creating a truly circular economy for polyurethane.

Overall, the breakthrough in recycling technology developed by the researchers at Aarhus University offers a promising solution to the environmental challenges posed by polyurethane foam waste. By recovering and reusing the main components of PUR foam, the industry can reduce its reliance on virgin materials, minimize waste, and move towards a more sustainable future. While there are still challenges to overcome, the potential benefits of this innovative recycling method are clear, making it a significant step forward in the quest for a more environmentally friendly approach to polyurethane production and disposal.

Leave a Reply