Piezoelectric materials are central to various high-tech applications, especially in the fields of medical imaging and underwater sonar technology. Their ability to convert mechanical stress into electrical charges makes them indispensable in generating and sensing ultrasound waves. Specifically, these materials often serve as the backbone for devices that require precise manipulation of sound waves, enabling advancements in both diagnostics and technology utilization. However, the effectiveness of these materials can be compromised when subjected to heat and pressure, thereby necessitating innovative solutions that can facilitate their restoration without compromising device integrity.

Traditionally, when piezoelectric materials, particularly relaxor-PbTiO3 crystals, lose their optimal properties due to thermal or mechanical stress, the only recourse has been disassembly and high-temperature treatment. This practice not only poses logistical challenges but also raises significant concerns regarding material wastage. For example, devices might need to be completely re-engineered or new materials sourced to address faults, resulting in increased cost, time, and environmental impact. Within temperature ranges as low as 70°C, even standard shipping and storage can lead to misalignment in these materials, complicating the lifecycle management of valuable components. The urgency to find a more efficient and less invasive method for maintaining the piezoelectric properties thus becomes apparent.

Researchers have recently developed an ingenious method that addresses these challenges by allowing the re-poling of piezoelectric materials at room temperature. Published in *Nature Communications*, the study outlines how the traditional model of heat-dependent restoration is being transformed. This groundbreaking technique enables the alignment of dipoles—the molecular pairs responsible for the piezoelectric effect—without requiring the brutal conditions of heat treatment, thereby preserving the overall integrity of the ultrasound devices and extending their functional lifespan.

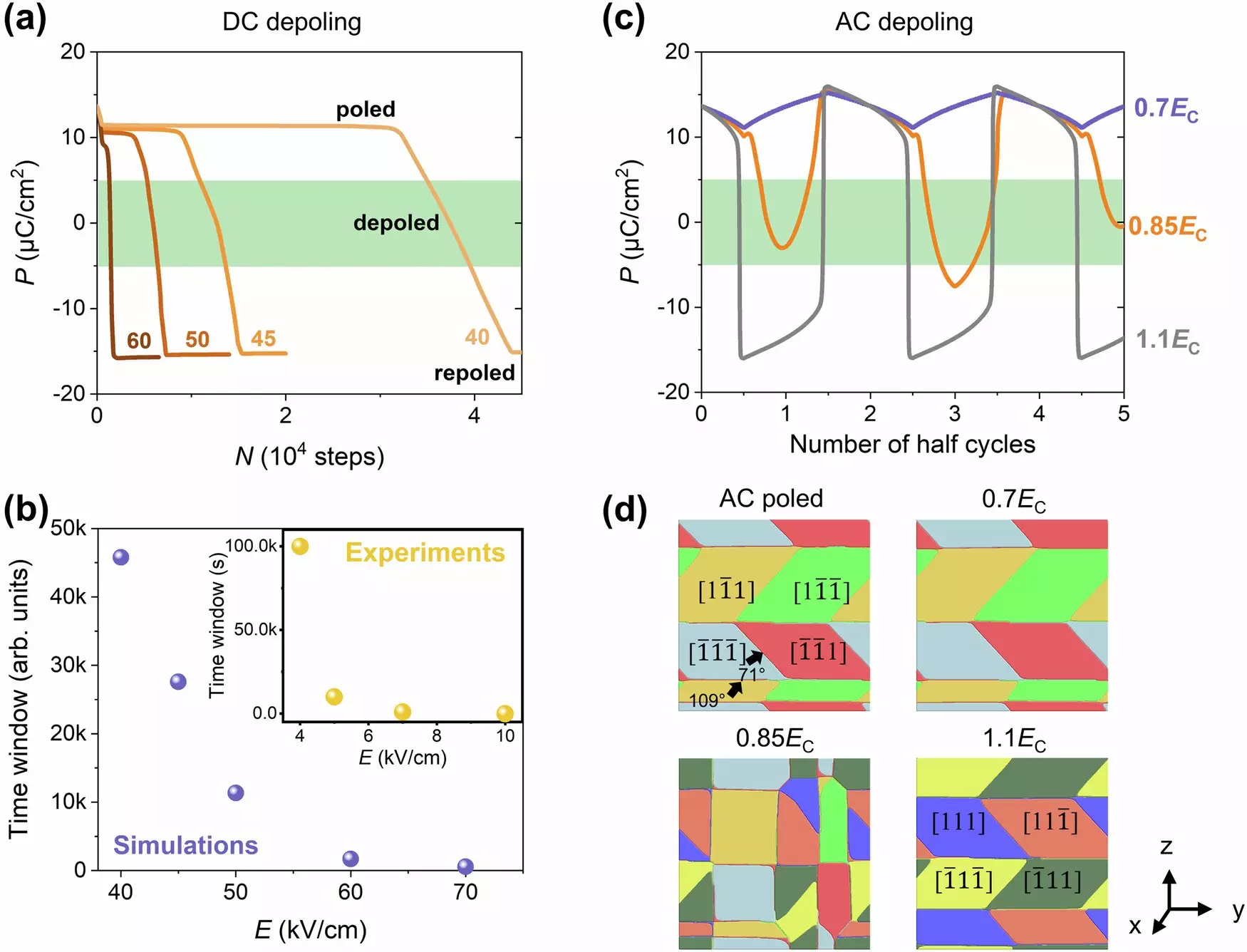

The technique hinges on the application of an alternating current (AC) electric field, a method that has previously been underutilized. Traditionally, a direct current (DC) field was the go-to approach for aligning dipoles; however, it has the significant drawback of being ineffective for depoling. The researchers discovered that applying an AC field can effectively target both the alignment and re-alignment of dipoles, making it possible to bring misaligned components back into functional status at room temperature.

The ramifications of this innovation stretch far beyond mere restorative capabilities. The flexibility introduced by room temperature poling opens avenues for the design of next-generation ultrasound devices that are not restricted by previous limitations on material selection and manufacturing processes. Manufacturers can now consider a wider variety of materials without the persistent worry over their impact on piezoelectric performance.

For instance, in a manufacturing context, companies could innovate new designs that incorporate previously infeasible materials, boosting overall device efficiency and reducing costs. This newfound freedom could catalyze advancements in ultrasound technology, pushing the potential of medical diagnostics, environmental monitoring, and various industrial applications to previously unattainable heights.

Moreover, there are broader implications to consider from both an environmental and economic standpoint. The ability to restore piezoelectric materials at room temperature reduces waste and conserves valuable resources. Since these components are often expensive, the efficiency improvements could lead to significant cost savings across industries utilizing ultrasound technologies. Efficient use of materials would not only optimize production processes but also align with global sustainability efforts aimed at reducing the environmental footprint of technological advancement.

The capability to restore piezoelectric materials at room temperature is set to revolutionize the landscape of ultrasound technologies. With potential applications spanning diverse fields, from healthcare to environmental science, the implications of this advancement are extensive. As research continues to uncover additional capabilities within the manipulation of piezoelectric materials, we may very well witness unprecedented leaps in technology, underscoring the crucial need for ongoing innovation in material sciences. By moving beyond traditional practices, we open the door to a future rich with possibilities, reinforcing the importance of adaptive strategies within the realm of high-tech manufacturing and application.

Leave a Reply