In an era where sustainable energy solutions are paramount, hydrogen has emerged as a leading candidate in the quest for efficient energy storage and delivery. Hydrogen fuel cells utilize this gas to produce electricity, with water being the only byproduct, making it an environmentally friendly alternative. However, traditional methods of hydrogen production face significant challenges, especially when it comes to reliably harnessing renewable energy sources. The recent work by a collaborative research team shines a light on how to overcome these hurdles through innovative catalyst development that enhances the reliability of alkaline water electrolysis systems—an essential method for hydrogen generation.

Understanding Alkaline Water Electrolysis Systems

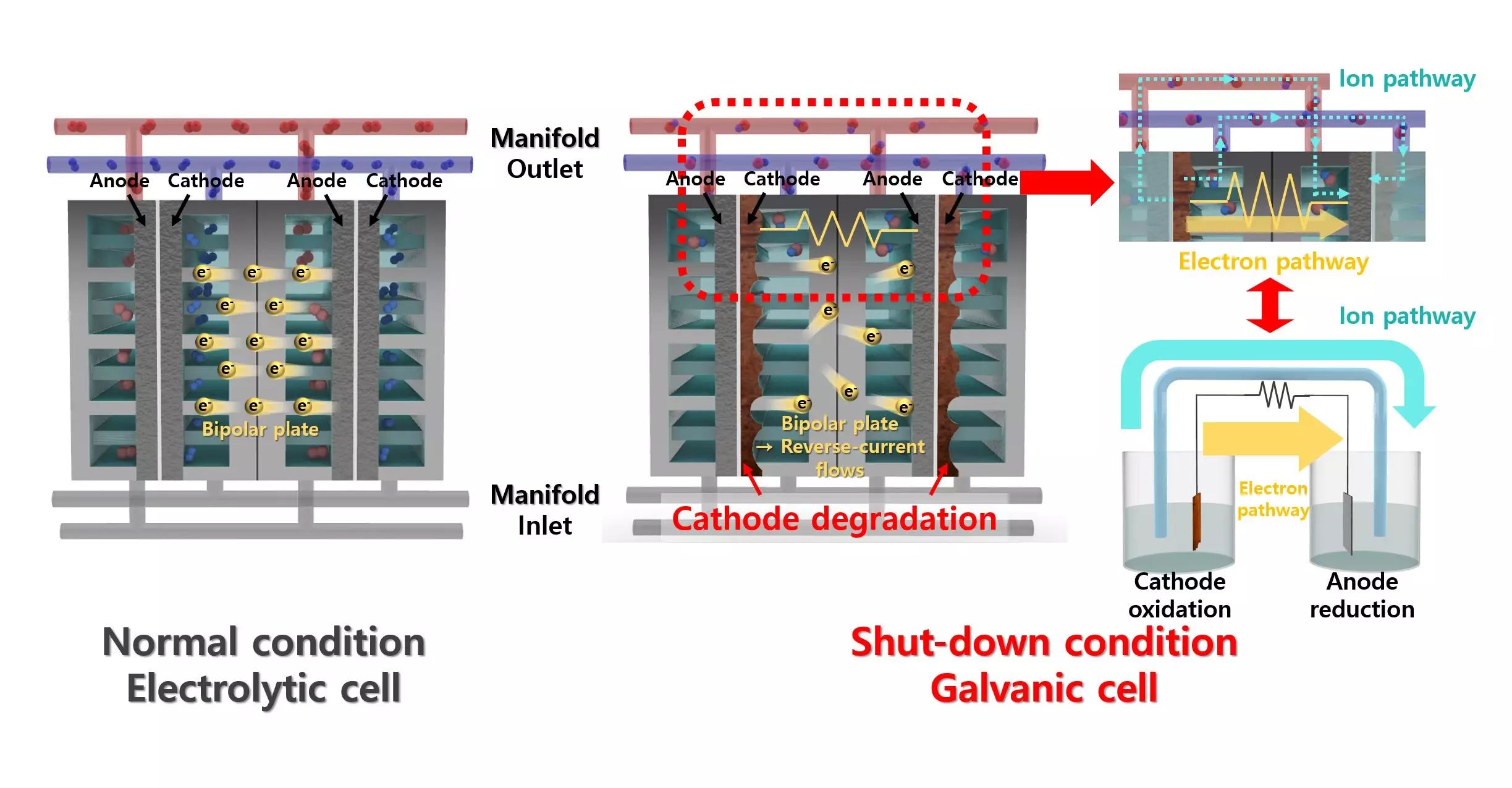

Alkaline Water Electrolysis (AWE) provides a cost-effective and robust way to produce hydrogen by splitting water molecules using electricity. However, the effectiveness of this method is often hindered by the inherent fluctuations in renewable energy sources. As renewable generation responds to weather and climate conditions, the resulting intermittency leads to instances of reverse current during power outages, which can damage the electrolyzer’s electrodes. This degradation not only impacts efficiency but also compromises the longevity of the system, raising concerns for large-scale implementations.

Innovative Solutions: The Role of Lead Coating

The research spearheaded by Professor Jeong Woo Han and his team at Pohang University of Science and Technology (POSTECH) tackles this critical issue with an ingenious solution: a lead (Pb) coating on the nickel (Ni) catalyst used in AWE. Traditionally overlooked due to lead’s low catalytic activity, this innovative approach surprisingly reveals that lead can enhance the performance of nickel rather than hinder it. By acting as a co-catalyst, lead promotes essential reactions such as proton desorption and water dissociation, thereby increasing hydrogen production efficiency.

Significant Findings and Implications

The researchers not only demonstrated that this lead-coated catalyst significantly improves hydrogen evolution efficiency but also that it exhibits remarkable resistance to reverse current. This dual functionality addresses a significant technological limitation that has plagued previous catalyst developments. Unlike their predecessors that required additional equipment to manage reverse current, this newly minted catalyst achieves this with a straightforward lead application, symbolizing a leap forward in catalyst design philosophy.

A New Frontier in Hydrogen Research

The implications of this research stretch far beyond academic curiosity; they signal a potential paradigm shift in how hydrogen is produced and utilized on a larger scale. Professor Yong-Tae Kim’s assertion that this is the first study to effectively tackle the degradation caused by reverse currents with a material-based solution positions this work at the forefront of hydrogen technology. As we seek to transition to greener energy infrastructures, innovations like this will be critical in deploying reliable hydrogen production systems that can keep pace with our fluctuating energy needs.

The convergence of novel material science and energy production holds the potential to reshape our energy landscape and drive the momentum towards a sustainable future. Innovations such as the lead-coated nickel catalyst represent not just an advancement in hydrogen production, but a beacon of hope for an energy-dependent world striving for greener solutions.

Leave a Reply