Fluid management in various sectors is crucial, yet it remains an arduous task due to conventional inadequacies in handling liquid substances. From healthcare to pharmaceuticals, the effective capture, transfer, and release of fluids form the backbone of operating procedures. Recent innovation from The Polytechnic University of Hong Kong (PolyU) sheds light on this long-standing problem with a groundbreaking development known as Connected Polyhedral Frames (CPFs).

Despite advances in solid matter manipulation techniques, the management of liquids has remained a complex challenge. The inherent properties of fluids, such as their tendency to wet and spread across surfaces, lead to inefficiencies and imprecise transfers. Instruments used to manipulate fluids often suffer from inaccuracies, which can cause cross-contamination and hamper the integrity of tests and procedures. This inefficiency not only affects the accuracy of measurements but also contributes to the environmental crisis through the misuse of single-use plastics like pipettes and microtubes.

CPFs have emerged as a promising solution to this dilemma, fundamentally altering the way in which liquids can be manipulated. By utilizing a revolutionary structure, researchers have designed a fluid processing platform that emphasizes both versatility and precision, addressing key primary challenges inherent in traditional fluid management systems.

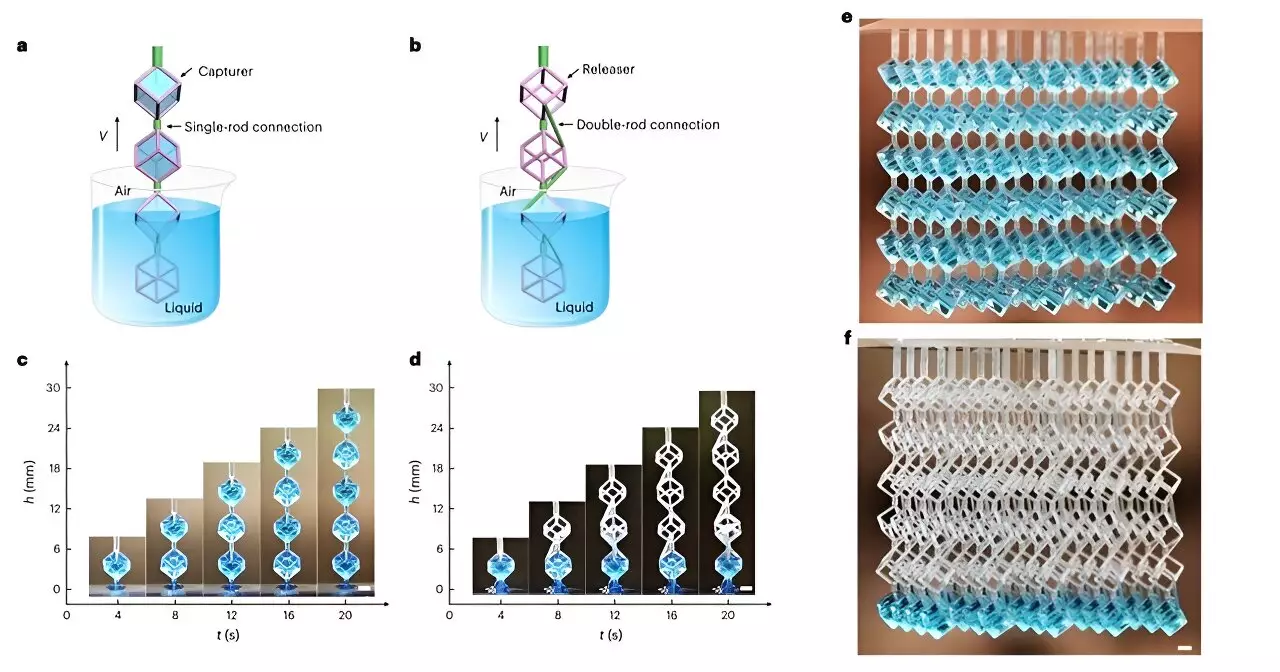

At the core of CPFs lies a unique system that allows reversible switching—a crucial feature that enhances control during fluid manipulation. This system consists of single and double-rod connections positioned within polyhedral frames. The configuration enables the network to retain or release liquids dynamically, offering unprecedented freedom in how fluids can be processed.

In essence, frames positioned over single-rod connections operate to capture liquids by creating a seal that prevents leakage. Conversely, frames over double-rod connections facilitate liquid release through the formation of channels that promote liquid transfer. This dual functionality grants researchers the ability to harness fluids with utmost flexibility, ultimately leading to accurate volumetric processing.

The significance extends beyond simple capture and release; CPFs allow for three-dimensional programmable liquid patterns, spatial control over different material concentrations, and large-scale manipulation of multiple liquids. These newfound capabilities pave the way for various applications, extending into fields such as biotechnology, chemistry, and material science.

One of the most exciting applications of CPFs lies within the pharmaceutical arena, particularly concerning controlled drug release. The research conducted by Prof. Wang’s team illustrated the potential of CPFs in the 3D binary liquid patterning of vital nutrients like vitamins B2 and B12. By carefully manipulating gel thickness, the diffusion rates of these vitamins can be precisely controlled.

Such applications emphasize how CPFs can be utilized to encapsulate and deliver therapeutic agents effectively. Unlike traditional methods that may leave residuals or fail to release samples optimally, CPFs demonstrate significantly enhanced release capabilities, promoting higher release efficiency and accuracy during diagnostics and treatments.

Beyond pharmaceuticals, CPFs hold substantial promise in the field of biomaterial encapsulation—the process of enclosing biological materials within carriers for various uses. With potential uses spanning microbial reactions to efficient product yield projections, researchers can leverage CPFs to separate bacteria from their waste products more efficiently, enhancing the purification processes and maximizing operational efficiency.

The encapsulation technology demonstrated with the Acetobacterium offered insights into how CPFs can simplify complex microbial reactions, streamline processes, and facilitate improved bacteria utilization rates. As the world faces pressing concerns over global food production and biotechnology, CPFs could revolutionize agricultural processes through optimized microbial applications.

CPFs do not merely shine in the medical and biomedical domains; they possess transformative potential in environmental technology too. An early prototype of a humidifier utilizing CPFs has demonstrated increased water retention capabilities while ensuring lower overall water flow requirements. The implications for energy efficiency are substantial, as traditional systems often lead to excessive resource use.

In broader applications, CPFs can be effectively employed in CO2 capture and reutilization, a critical endeavor in combating climate change. The technology allows for superior gas absorption techniques, potentially heralding a new era for sustainable industrial practices.

The origination of Connected Polyhedral Frames at PolyU represents a significant advance in fluid management technologies, promising a shift away from conventional challenges faced in liquid handling. By enhancing accuracy, versatility, and performance, CPFs not only target immediate challenges but also set the stage for novel scientific explorations across diverse fields. As society increasingly turns to innovative solutions for age-old problems, CPFs exemplify the power of merging ingenuity with practical application, leading to potential breakthroughs that not only advance technology but also fortify sustainability efforts for the future.

Leave a Reply