In a significant advancement in the field of 3D printing, researchers from the University of California San Diego have unveiled a novel method utilizing a straightforward combination of polymer ink and salt water solution. This innovative technique, featured in the reputable journal Nature Communications, promises to redefine how materials are manufactured by making the process more sustainable and ecologically responsible.

The Mechanics of the Process

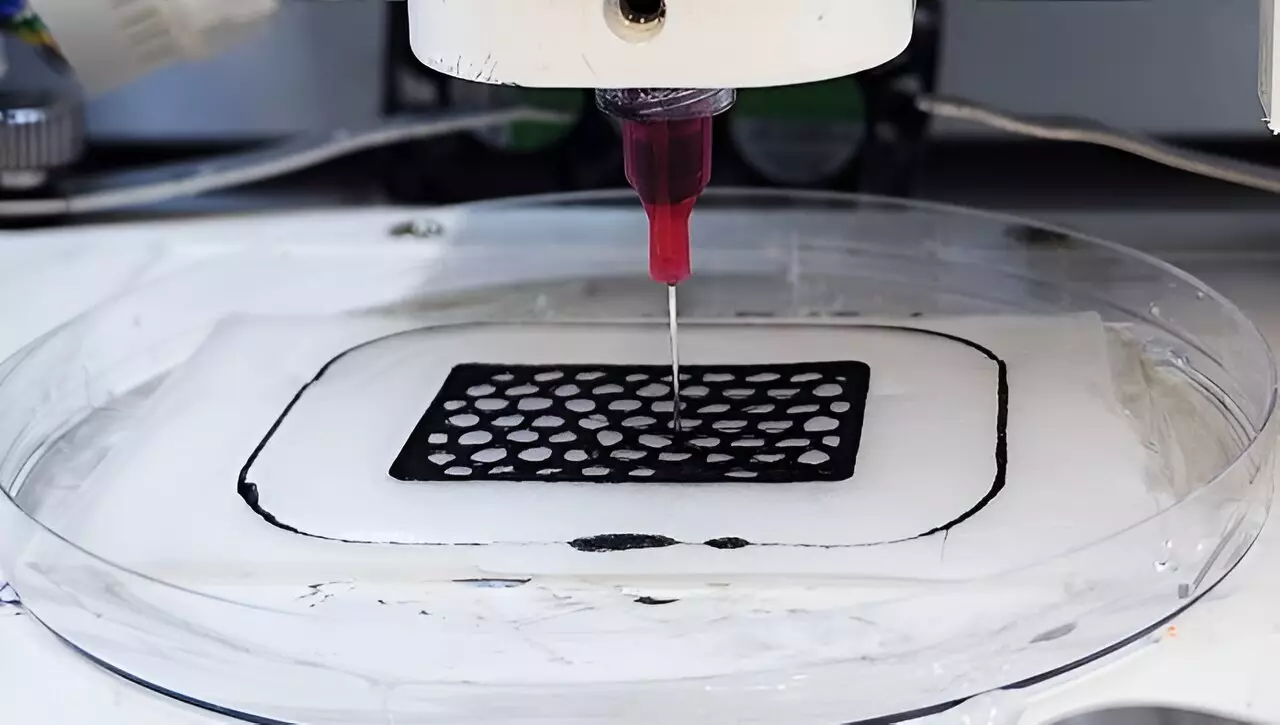

At the heart of this groundbreaking approach is a liquid polymer known as poly(N-isopropylacrylamide), abbreviated to PNIPAM. The ingenuity of this method lies in its simplicity: when the PNIPAM ink is extruded through a nozzle into a calcium chloride salt solution, a rapid solidification occurs upon contact. This phenomenon is attributed to the salting-out effect, wherein salt ions exert a strong pull on the water molecules present in the polymer solution. As water is drawn out, the hydrophobic polymer chains cluster together, resulting in the immediate formation of solid structures.

Jinhye Bae, a senior author of the study and a professor in the Aiiso Yufeng Li Family Department of Chemical and Nano Engineering at UC San Diego, notes the significant advantages of this process. Unlike traditional solidification methods that often involve energy-intensive measures and harsh chemicals, this new technique operates efficiently at room temperature and does not require elaborate equipment or additional toxic substances.

One of the standout features of this innovative process is its environmentally friendly nature. It circumvents the need for high-energy inputs and reduces the environmental footprint typically associated with polymer manufacturing. Moreover, the ability of the solid structures to dissolve back into a liquid form when exposed to fresh water provides a unique opportunity for recycling the ink. This reversibility is a game-changer in the industry, as it facilitates a more sustainable life cycle for polymer materials.

Bae emphasizes that this method not only helps in creating sustainable products but also opens new avenues for recycling polymer materials, aligning with growing global demands for eco-friendly manufacturing practices.

The research team demonstrated the versatility of their method by incorporating other materials into the PNIPAM inks. A notable example includes the successful printing of an electrical circuit containing carbon nanotubes, capable of powering a light bulb. Yet again, these circuits, upon dissolution in fresh water, return to their initial liquid state, highlighting the promise of creating water-soluble and recyclable electronic components.

This approach can revolutionize the way we think about electronics and components, especially in the realm of sustainability. Bae’s team foresees this technique being integral to future advances in environmentally responsible polymer manufacturing technologies, fostering a new generation of products that are not just effective but also gentler on the planet.

Overall, the development of a 3D printing method using PNIPAM and salt water not only exhibits remarkable efficiency and practicality but also champions a paradigm shift in how we manufacture materials. With its ability to recycle and reconstitute without compromising on effectiveness, this technique could herald a new era of sustainable manufacturing, aligning technological advancement with environmental responsibility. The implications are vast, promising a future where innovation and ecology harmoniously coexist.

Leave a Reply