As the world increasingly shifts towards renewable energy and technologies with lower carbon footprints, the demand for rare-earth elements (REEs) is skyrocketing. These elements, particularly neodymium (Nd) and dysprosium (Dy), are crucial for manufacturing high-performance magnets found in devices like electric vehicles (EVs) and wind turbines. The pressing need for sustainable practices in the extraction and recycling of these critical materials becomes evident, given their importance in facilitating an energy-efficient future. Traditional methods for recycling REEs are often fraught with environmental drawbacks and inefficiencies, which brings to light the significance of innovative approaches in this field.

A groundbreaking study from Kyoto University has introduced a pioneering approach called the selective extraction-evaporation-electrolysis (SEEE) process. This method promises to transform how we recycle REEs from end-of-life magnets, addressing both efficiency and environmental impact. Under the leadership of Professor Toshiyuki Nohira and his dedicated research team at the Institute of Advanced Energy, the study seeks to revolutionize recycling technologies integral to green innovations.

The SEEE process represents a departure from longstanding, energy-intensive recycling methods by integrating a three-phase approach optimized for sustainability. The inclusion of molten salt mixtures like calcium chloride (CaCl2) and magnesium chloride (MgCl2) exemplifies the shift towards a more environmentally conscious technique.

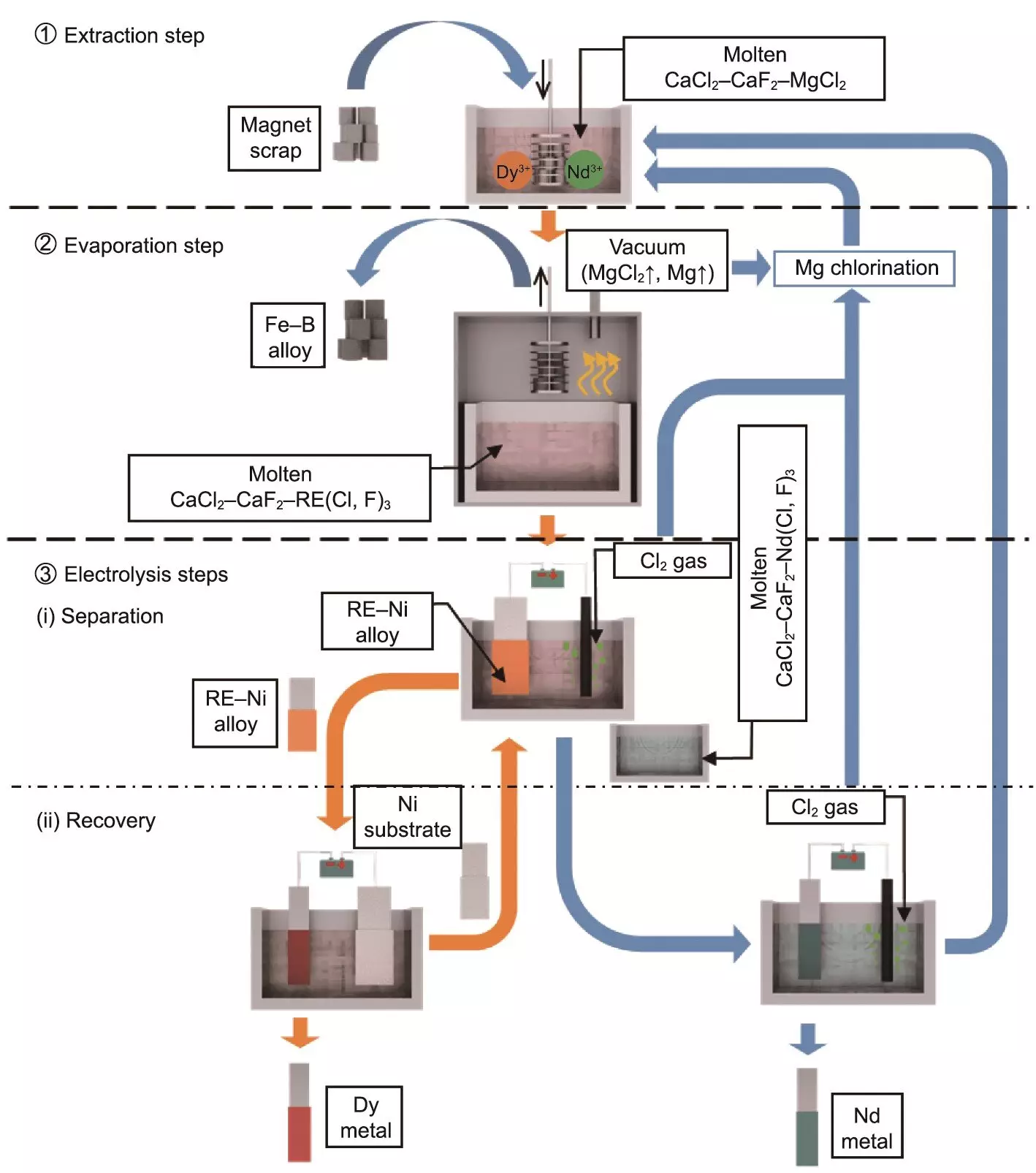

The SEEE process comprises three distinct, yet interconnected stages: selective extraction, selective evaporation, and selective electrolysis. Each phase plays a vital role in executing the thorough recovery of REEs from magnet scraps.

1. **Selective Extraction**: The initial stage employs a molten salt medium that effectively extracts desirable REEs from discarded magnets. Notably, the addition of calcium fluoride (CaF2) enhances the efficiency of extraction while minimizing material loss during the process.

2. **Selective Evaporation**: Once extraction is complete, the subsequent step involves the removal of residual extraction agents and byproducts. This not only concentrates the REEs but also streamlines the material for the final stage.

3. **Selective Electrolysis**: The last step employs electrolysis to separate the extracted REEs based on their distinct electrochemical properties. This advanced method is key to recovering high-purity neodymium and dysprosium metals, providing an output exceeding 90% purity.

The results from the SEEE process are nothing short of impressive. Recovery rates of 96% for neodymium and 91% for dysprosium illustrate the potential of this approach to yield high-quality materials for reuse. This level of efficiency in separating and recycling vital elements signifies a substantial improvement over existing methods and supports the global push for more sustainable recycling solutions.

Critical to future green technology practices, this study highlights the importance of effectively recycling REEs. As the reliance on electric vehicles and renewable energy systems escalates, methods like the SEEE process could operationalize sustainable resource management, thereby minimizing our dependence on environmentally detrimental mining practices.

While the focus of the research is on neodymium magnets, the applicability of the SEEE process extends beyond just this singular domain. Researchers propose adaptability for various industrial applications, including nuclear fuel reprocessing. This versatility could inspire further innovations in materials recovery across different industries, reinforcing the need for comprehensive solutions to address environmental challenges.

Although the SEEE process has showcased remarkable potential, researchers recognize the necessity for additional studies to facilitate a seamless integration into large-scale industrial operations. The initial findings, however, mark a promising leap forward in bridging the gap between advanced materials recycling and ecological sustainability.

The emergence of the SEEE process marks a pivotal moment in the quest for efficient and environmentally responsible recycling methods. As we grapple with the environmental implications of our rapidly industrializing world, innovative technologies like the SEEE approach illustrate the vital intersection of sustainability and material science. As research continues to evolve, solutions stemming from interdisciplinary efforts such as these will undoubtedly shape a carbon-neutral future by addressing the pressing challenges surrounding rare-earth element recycling.

Leave a Reply