Catalysts play an integral part in the chemical industry, facilitating over 90% of the products we engage with daily. These chemical agents are capable of accelerating reactions and lowering the energy threshold required for various processes. Indeed, some reactions would be entirely unfeasible without the intervention of catalysts. This pivotal role underscores the importance of ongoing research to optimize their use, particularly concerning noble metals that are both rare and expensive. Recent studies from researchers at the Karlsruhe Institute of Technology (KIT) have unveiled innovative methods aimed at enhancing the stability of noble-metal catalysts while concurrently minimizing their material requirements, a dual benefit that could have far-reaching implications for sustainability.

KIT’s research investigates the behavior of noble-metal catalysts at the atomic level. Dr. Daria Gashnikova, the principal investigator associated with this study, emphasizes that the strategy the team has developed is designed to bolster catalyst stability, enabling the effective formation of active clusters. By meticulously examining commonly utilized supported catalysts, researchers aim to maximize catalytic efficiency with minimal noble metal consumption. This research is of paramount importance as noble metals are not only finite resources but also pose environmental challenges due to their mining and processing.

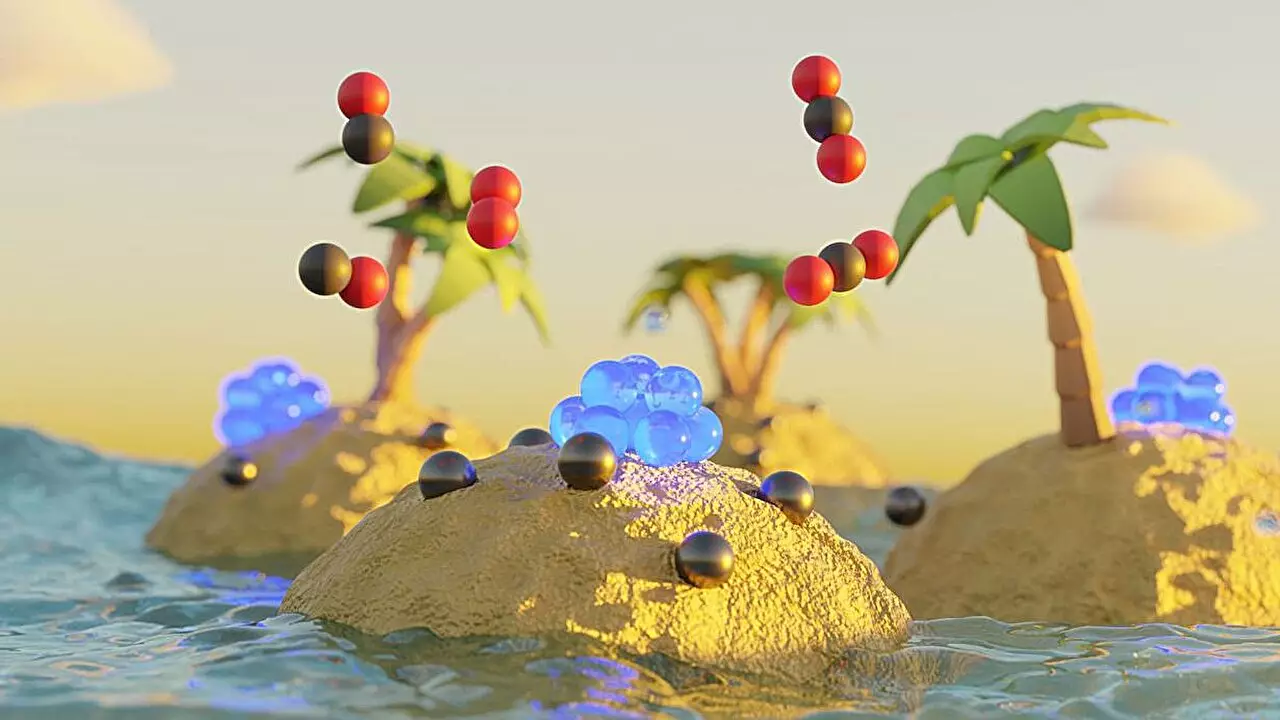

The study of supported catalysts reveals pertinent insights into their structural dynamics. In essence, noble metals are deposited as nanoparticles on a supporting material, facilitating the desired chemical reactions. However, these particles are not static; they are prone to structural changes influenced by varying reaction conditions. This dynamic behavior can lead to two problematic phenomena: the aggregation of nanoparticles into larger clusters, which reduces the available surface area for reactions, and the disassembly of these clusters into single atoms, which lack catalytic effectiveness. Both scenarios diminish the overall performance of the catalyst and pose significant challenges to industrial applications.

The groundbreaking approach devised by the ITCP researchers exploits the different interactions that noble metals exhibit with various supporting materials. By selecting appropriate supports, it is possible to foster an environment conducive to maintaining smaller, more efficient catalytic clusters. This nuanced understanding of metal-support interactions opens a new avenue for the development of more effective catalysts that not only perform better but require fewer resources to produce. As a result, the advancement has significant implications for both sustainability and economic efficiency within the chemical industry.

The research conducted at KIT is a pivotal step toward the sustainable use of noble metals in catalysts. By enhancing the stability of these crucial substances and reducing their required quantities, there lies potential for significant environmental benefits and cost reductions. As the chemical industry continues to evolve, innovations in catalyst design like those introduced by the KIT team promise to play an essential role in promoting a more sustainable future, aligning economic practicality with ecological responsibility. This advancements remind us that scientific inquiry not only propels industry forward but also shapes the environmental landscape of our planet.

Leave a Reply