In an era where technology continually strives to surpass conventional boundaries, remarkable strides are being made in the realm of materials science. The recent work of a team of researchers pushes the envelope by merging advanced nanotechnology with 3D printing methods to develop a novel type of hydrogel. This standout innovation showcases hydrogels that can alter their shape in response to light, demonstrating a controlled movement that can be activated remotely. This breakthrough not only awakens possibilities in technological applications but also raises intriguing questions about the future of smart materials.

The Mechanics Behind 3D-Printed Hydrogel Actuators

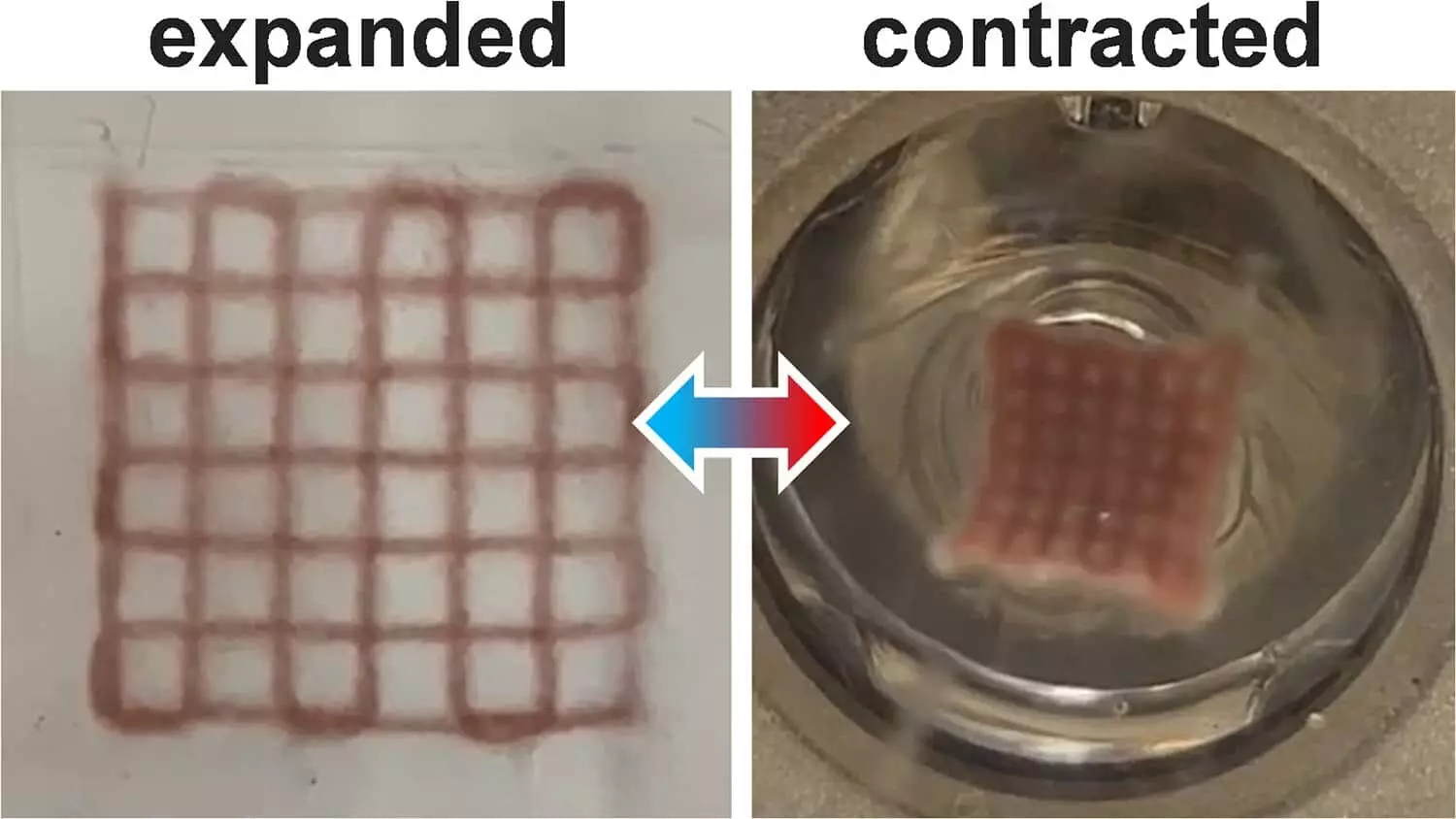

At the core of this innovation are gold nanorods embedded within a hydrogel matrix. These nanorods are remarkable for their ability to absorb light and convert it into heat—a feature that initiates the contraction of the hydrogel’s polymer structure. As the material cools upon removal of the light source, the hydrogel expands again. This remarkable cyclic behavior offers tremendous potential for utilitarian applications in diverse domains such as robotics, biomedicine, and environmental sensing technologies.

One of the pioneers behind this project, Joe Tracy from North Carolina State University, identifies the need for sophisticated design flexibility offered through 3D printing technology. Conventional methods, which often involve the imposition of heat or other mechanical stimulation, become impractical in systems requiring fine-tuned control over their movement. The ability to remotely trigger actuation using light makes these newly developed hydrogels an attractive alternative.

Processing Challenges and Innovative Solutions

The creation of these photoresponsive hydrogels wasn’t without its challenges. Traditional 3D printing relies on materials that maintain a stable viscosity to hold their shape. The novel mixture utilized in this research, however, provides a low viscosity solution, akin to a gelatinous substance, which presented formidable difficulties for initial printing efforts. The solution lay in a clever approach involving printing the hydrogel mix into a ‘gelatin slurry’—a unique backing that allowed the printer nozzle to move freely while maintaining an organized structure.

This ingenious adaptation addresses a fundamental problem: enabling the light to penetrate the supportive medium to expedite hydrogel solidification. By letting the light trigger cross-linking of the polymers, the researchers effectively cemented their breakthrough. The subsequent elimination of the gelatin leaves behind a robust, intricately designed hydrogel capable of dynamic movement.

Broadening Horizons Through Technology

As the implications of this technology become clearer, it is essential to consider how these smart hydrogels can be utilized across various fields. One intriguing application could be in the design of soft robotics, where traditional mechanical actuators come with inherent limitations, including weight and rigidity. Soft robots could mimic natural organisms more effectively using these hydrogels to simulate muscle contractions and extensions through mere light manipulation.

Moreover, the capacity for remote actuation also opens avenues for deploying this technology in delicate and hazardous environments where physical interaction proves risky. Envision an operating room where minimally invasive surgical tools made from these hydrogels can be controlled with precision, creating a revolutionary approach to patient care.

A New Era for Design Freedom

Beyond practical applications, the artistic potential for these 3D-printed hydrogels is staggering. Designers and engineers enjoy unprecedented freedom to invent complex forms that can respond dynamically to stimuli, expanding the creative possibilities in product design, art installations, and architecture. This flexibility stands in stark contrast to traditional mold-casting methods, where limitations often force compromises in design.

As the field of responsive materials advances, the interplay between technology, design, and application becomes increasingly intertwined. The creativity fueled by such innovations invites fresh conversations around environmental sustainability, human interaction, and metamaterials. This juxtaposition of artistry and science redefines our relationship with the materials that shape our world.

The fusion of gold nanorods with 3D-printed hydrogels heralds a transformative era, where capability meets creativity, and light unlocks potential that may very well change the fabric of our technologies. As this research evolves, so too does our understanding of what materials can do, promising an exciting future full of possibilities never before imagined.

Leave a Reply