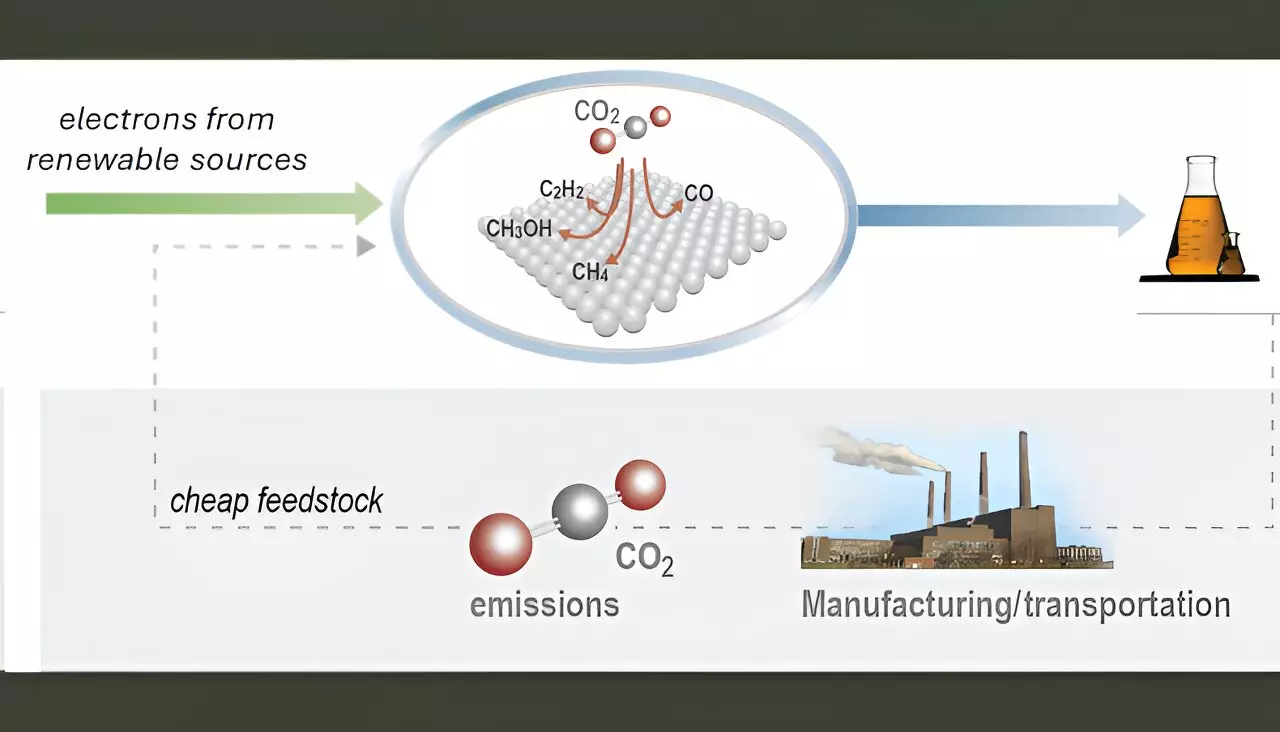

In the quest for sustainable solutions to combat climate change, the conversion of carbon dioxide (CO2) into valuable chemicals and fuels stands as a promising avenue. Coupling this process with renewable energy sources, such as solar or wind power, offers an opportunity for eco-friendly production of essential chemicals like ethylene and ethanol. These products are sought after both as feedstocks in the chemical industry and as fuels for transportation. This dual benefit makes CO2 electrochemical conversion not only a feasible approach for waste reduction but also a crucial step in the transition to a low-carbon economy.

Traditional methods have seen certain advances, particularly in the design and efficiency of electrolyzers—devices that convert electricity into chemical energy. However, challenges remain, primarily concerning the stability and selectivity of the catalysts deployed in these systems. Catalysts are essential in driving the reactions that convert CO2 into usable forms, and their effectiveness can significantly impact the viability of large-scale implementation.

Researchers at Lawrence Livermore National Laboratory (LLNL), in collaboration with various academic institutions and industry partners, have made strides in addressing these challenges through an innovative catalyst coating platform using physical vapor deposition (PVD). The PVD technique, known for its precision, allows for meticulous control over several catalyst properties, including thickness, composition, and surface morphology. By employing this method, the team successfully developed catalysts capable of producing multi-carbon products from CO2, addressing a critical need in both industry and environmental sustainability efforts.

A significant breakthrough in this research was the focus on copper and its alloys, which, until recently, had been the only materials effective at converting CO2 into a range of multi-carbon products, such as propanol and acetate. Catalysts have typically been a bottleneck in the commercial scalability of CO2 conversion technologies. The LLNL researchers aim to separate catalyst performance from the challenges posed by integration and fabrication methods, which can skew the results and hinder progress.

The collaboration has yielded a novel scalable catalyst platform that enables the refinement of catalyst composition without altering the underlying structure. This innovation promises to streamline the evaluation of copper-based dilute alloy catalysts—materials that pose synthesis and integration challenges under traditional approaches. Led by materials scientist Juergen Biener, the team’s work and conceptual framework outlined in the journal Small spotlight the potential of dilute alloys in optimizing the processes involved in CO2 reduction reactions.

By utilizing theoretical insights, the researchers were able to structure the catalysts to amplify the efficacy of CO2 electrolysis. The results further demonstrate that through systematic adjustments of the catalyst properties, the energy landscape of these reactions can be modified, fueling the development of cleaner feedstocks essential for industries heavily reliant on chemical processes.

The advantages of PVD techniques extend beyond improved catalyst performance; they also offer economic benefits. Compared to traditional electrodeposition methods, PVD is less wasteful and requires fewer labor resources despite initial higher capital investment in equipment. As this technology matures, it has the potential to lower the costs associated with producing sustainable chemical feedstocks.

The implications of this research are profound, hinting at a future where CO2 is not merely a waste product but a central component of sustainable chemical synthesis. Such advancements could propel the chemical and transportation sectors toward significantly reduced carbon footprints, aiding global efforts in the fight against climate change.

The steps taken by LLNL and its partners underline an important shift in the perception of CO2: from a harmful greenhouse gas to a vital resource for the production of essential products. As research continues to enhance our understanding and manipulation of catalytic processes, there is hope that the integration of renewable energy into CO2 conversion strategies will pioneer new pathways toward a sustainable and resilient economy, addressing both energy needs and environmental concerns in tandem. The ambition is clear; as technology evolves, so too must our approach to climate change, leading us toward a greener, more sustainable future.

Leave a Reply