Plastic pollution has become an increasingly critical environmental challenge, impacting ecosystems and human health worldwide. Among the various types of plastic, polyethylene terephthalate (PET) is particularly prevalent, found in ubiquitous items such as plastic bottles and textiles. This widespread usage renders efficient recycling practices imperative, yet the current recycling rates for PET remain dismally low. The need for innovative recycling methods that transform waste back into useful raw materials is urgent, and recent research may provide a viable solution.

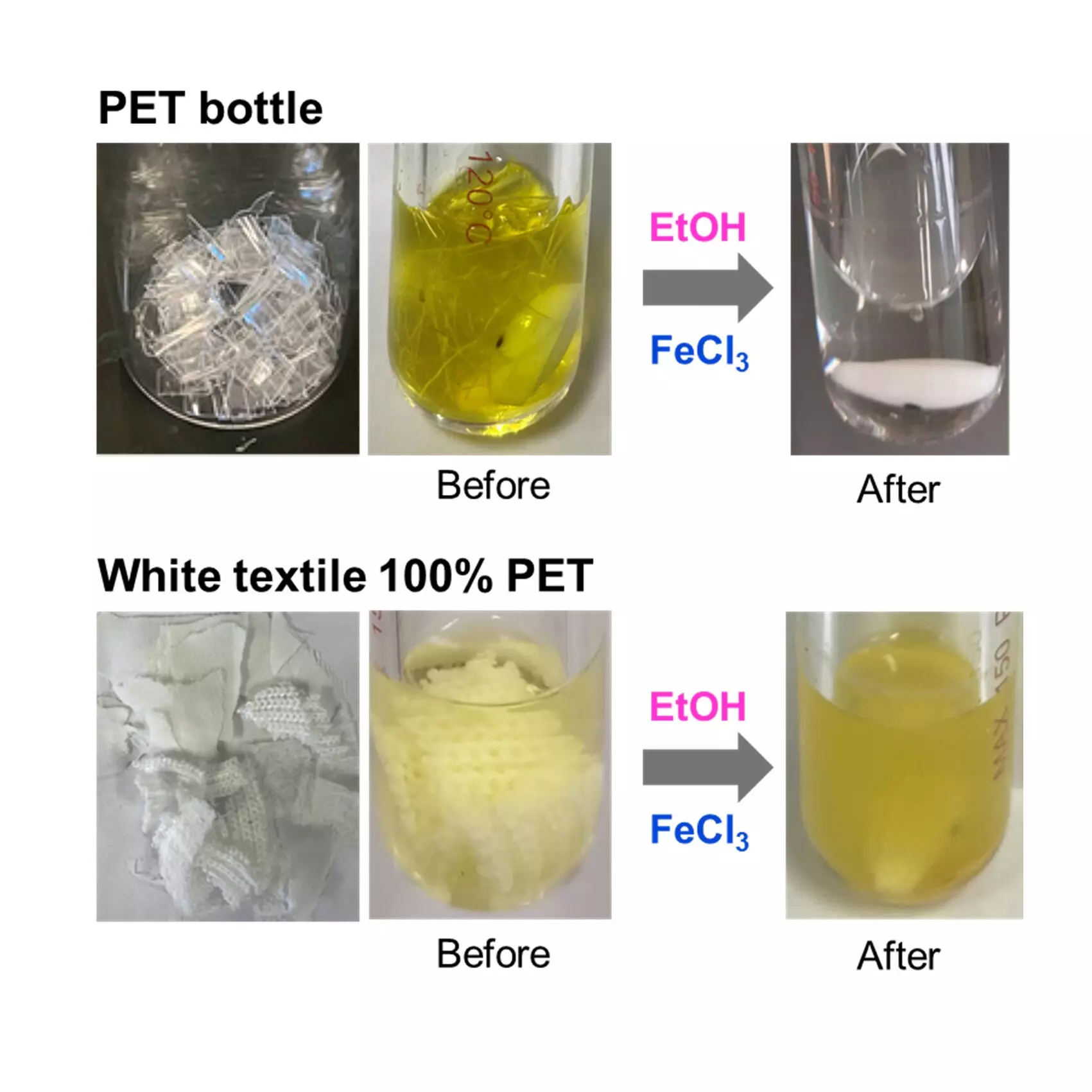

A pioneering study led by Professor Kotohiro Nomura at Tokyo Metropolitan University has introduced a new method for the depolymerization of PET, utilizing common alcohols in conjunction with the affordable iron trichloride catalyst. Published in the journal **Industrial Chemistry & Materials**, this research seeks to address the complexities involved in the recycling processes of PET, particularly in mixed waste scenarios that combine textiles and plastics.

Traditionally, chemical recycling of polyesters like PET requires extreme heat and a morally questionable amount of corrosive acids or bases. This cumbersome process leaves a significant gap in the development of sustainable recycling practices. By introducing a cost-effective, environmentally friendly alternative that operates without these harsher chemical compounds, Nomura’s team is making strides towards efficient recycling.

The developed methodology allows for the selective decomposition of PET into its constituent monomers, notably diethyl terephthalate (DET) and ethylene glycol (EG). Operating at relatively moderate temperatures of 160–180°C while achieving an impressive 98–99% selectivity for these outputs, this approach unveils notable advantages over previously employed titanium catalysts. By employing readily available iron chloride or bromide catalysts, the research positions itself as a more accessible and economically viable option.

Additionally, the method excels in the selective depolymerization of textile waste, which typically comprises a blend of polyester and cotton. This innovative research demonstrates the dual capability of recovering cotton alongside the PET components, thus streamlining the recycling process by mitigating contamination risks and enhancing material purity.

As global environmental policies increasingly focus on sustainability, this research aligns seamlessly with efforts to foster a circular economy. The ability to efficiently recycle PET from mixed waste contexts not only represents a significant technological advancement but also opens the door to reducing the environmental burden from plastic waste. This selective chemical recycling approach not only benefits the environment by repurposing waste into valuable materials but also encourages wider adoption of recycling practices among industries and consumers.

The advances made by Professor Nomura’s team exemplify critical developments in the recycling landscape, promoting a future where plastic waste is not merely discarded but transformed back into valuable resources. By capitalizing on the availability of inexpensive catalysts and operating at lower energy requirements, the potential for broader implementation of these methods stands to offer a significant leap forward in tackling the plastic waste crisis.

Leave a Reply