Lithium-ion batteries (Li-ion batteries) form the backbone of modern energy storage solutions, and among the various materials under investigation, NCM811 (Nickel-Cobalt-Manganese) has emerged as a prominent candidate for cathodes due to its high energy density. However, the longevity and efficiency of NCM811 are impeded by the mechanical degradation that occurs during battery cycles. Specifically, the poly-crystalline structure of NCM811 is prone to cracking under stress, leading to the loss of active materials and subsequently diminishing the battery’s life cycle. As such, effectively monitoring and comprehending the chemo-mechanical evolution within these materials is vital for enhancing their performance and durability.

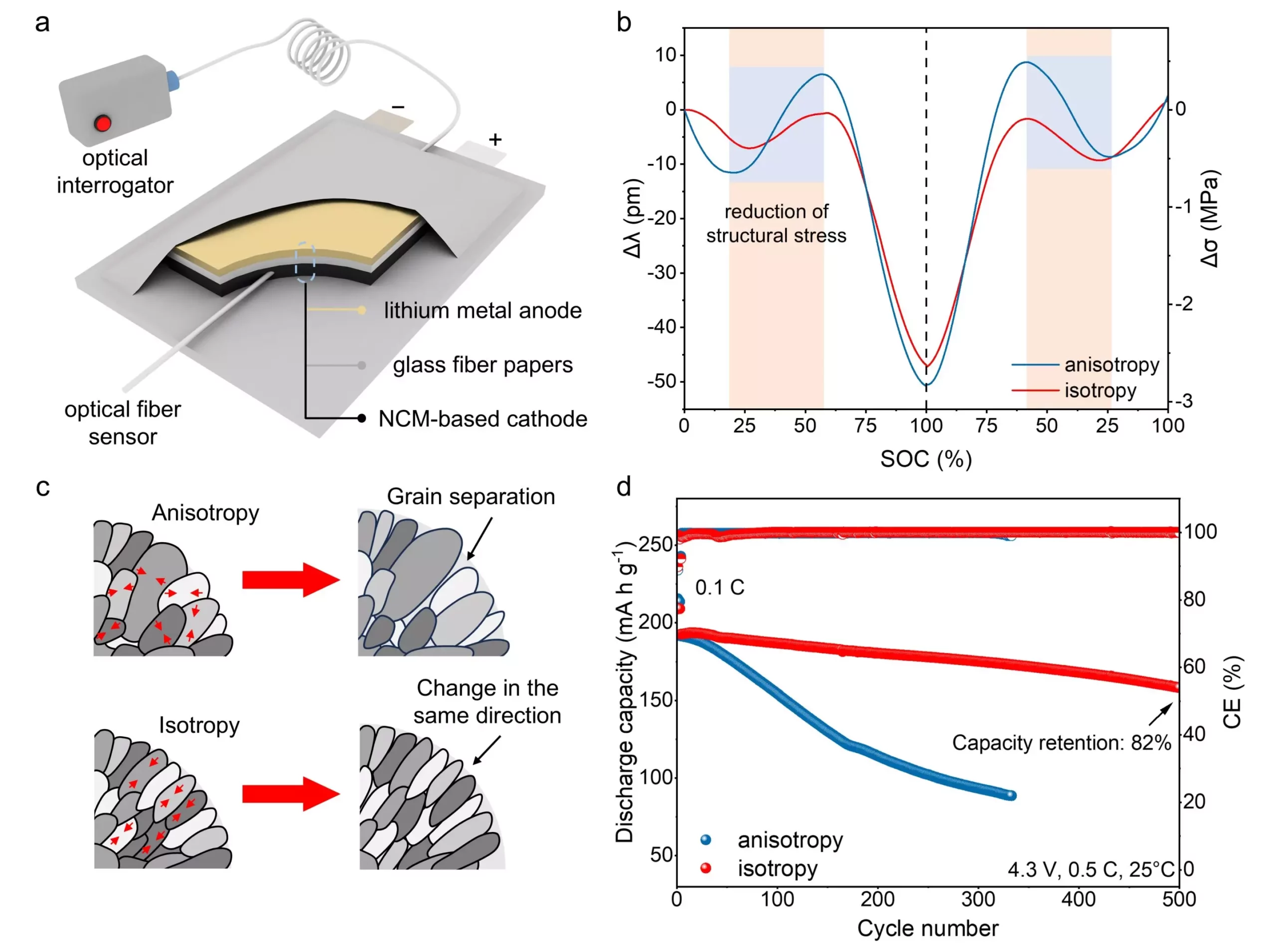

To tackle the pressing issue of mechanical stress in NCM811, a research team spearheaded by Professors Yunhui Huang and Zhen Li has introduced an innovative approach employing optical fibers. By integrating these fibers directly into the battery’s design, they have developed a method to continuously observe the stress evolution at the material level during operation. This novel optical sensing technique not only facilitates real-time monitoring but also ensures minimal impact on the battery’s overall performance due to the fibers’ small size and inherent chemical stability.

This integration has yielded important insights into the stress-related challenges faced by NCM811 materials. The research revealed that the stress evolution in poly-crystalline NCM811 is predominantly driven by two factors: chemical stress and structural stress. While the former, arising from the lithiation and delithiation cycles, is an expected part of battery operation, structural stress poses significant risks to the integrity and efficiency of the battery. Notably, the formation of cracks as a result of this structural stress can severely compromise battery performance over time.

The findings of the study illuminated the underlying causes of structural stress, pinpointing the nonuniform changes in the c-axis of the crystal structure during charging and discharging cycles as a primary factor. Furthermore, the anisotropic behavior of primary particles within the poly-crystalline material contributes significantly to this stress. Addressing these issues, the researchers proposed a strategic improvement in the spatial arrangement of these primary particles, aiming to create a more ordered structure that could better withstand mechanical stresses.

Through these efforts, they demonstrated that the structural stress can indeed be alleviated by optimizing the arrangement, which not only enhances the material’s stability but also leads to impressive performance metrics, such as a remarkable capacity retention of 82% after 500 charge-discharge cycles at a rate of 0.5C.

The practical applications of optical sensing in the monitoring of battery materials herald a new era in battery technology. As articulated by Prof. Huang, the potential of this technology extends well beyond mere stress detection; it also paves the way for the creation of more robust and intelligent battery systems. By continuing to refine the techniques for monitoring and managing the chemo-mechanical dynamics of cathode materials, researchers can significantly contribute to the advancement of safer and more efficient energy storage solutions in the future. The ongoing evolution of battery performance hinges on these groundbreaking innovations, promising a brighter energy landscape ahead.

Leave a Reply