The intricate field of metallurgy has evolved significantly since the early days of blacksmithing, where artisans intuitively discovered that deforming metals through techniques like hammering could enhance their strength. This fundamental principle, termed work hardening or strain hardening, remains pivotal in modern manufacturing processes, enabling the production of robust materials that underpin a myriad of industrial applications, from automotive frames to electrical infrastructure. However, a crucial limitation in material science has persisted for centuries: the inability to observe the work hardening process in real time. Recent breakthrough research from the Harvard John A. Paulson School of Engineering and Applied Sciences is changing that narrative.

For the first time, a dedicated team at the Harvard Materials Research Science and Engineering Center has been able to visualize the mechanisms that underlie work hardening, providing a fresh perspective that could significantly alter material design strategies. As articulated by Frans Spaepen, the senior author of the study, the advancement of large-scale computational models that predict work hardening efficacy is tightly linked to our understanding of the underlying physical principles that govern these interactions. The detailed study was published in the prestigious journal, Nature, marking a notable contribution to the field.

Traditionally, studying work hardening has been hindered by the inherent challenges in capturing atomic-level changes during deformation. Researchers had been limited to observations before and after the hardening process—leaving significant gaps in understanding the significant interactions that occur throughout deformation. With this new technique, the researchers were able to illuminate aspects of the work hardening process that had previously remained enigmatic.

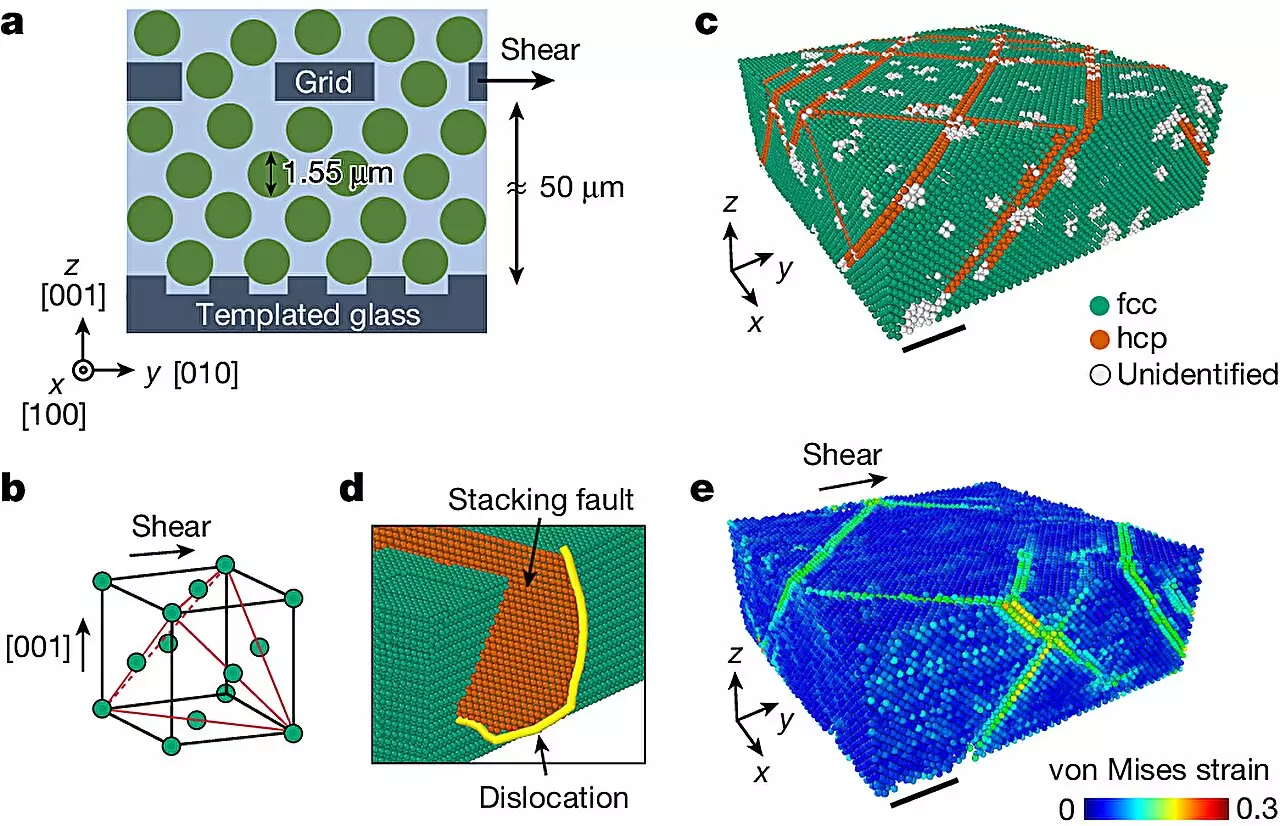

One of the most groundbreaking aspects of this research was the innovative approach of utilizing colloidal crystals—substantially larger particles that mimic the atomic structures of metals. These colloidal systems, which are on a scale 10,000 times larger than atoms, have been recognized for their ability to spontaneously form structured arrangements. While these colloidal crystals are markedly softer than their metallic counterparts, the research team found that they exhibit pronounced work hardening properties.

Utilizing confocal optical microscopy, every particle within these crystals was subjected to analysis during the application of strain. The incredible finding was that these soft materials presented a level of work hardening greater than what is seen in conventional metals such as copper and aluminum. The mechanics governing this phenomenon differ significantly from the expectations associated with traditional metal structures.

The research authors highlighted that the pronounced work hardening observed in colloidal crystals can be attributed primarily to the geometrical arrangement of particles and the interactions among defect structures known as dislocations. This new understanding provides insight into how defects interact and become entangled within the crystal lattice, resulting in enhanced material strength.

Ilya Svetlizky, a primary contributor to the research, noted that earlier studies had established that dislocations formed networks of defects contributing to work hardening; however, the full complexity of defect interactions was not fully elucidated. This latest study has illuminated the universal mechanisms of work hardening, thus broadening the scope of future material applications and designs.

The implications of these findings reach well beyond the confines of this study. By establishing that soft colloidal materials can exhibit extraordinary strength through the work hardening process, researchers open up new avenues for material innovation across industries. This discovery evokes consideration for not only current manufacturing practices but also the design of future materials that can exploit these newly understood principles.

David A. Weitz, another co-author, encapsulated the revolutionary impact of this research by stating that it reveals a fundamental truth about material strength—showing that softness does not preclude the possibility of high durability. The realization that the fundamental properties of materials can be manipulated based on structure presents exciting prospects for engineers and scientists alike.

As the realm of material science continues to expand, this pioneering research signifies a profound shift in our comprehension of work hardening dynamics. It transcends a mere academic curiosity; rather, it holds the potential to reshape industrial applications and inspire innovative material design. With the ability to observe and understand these processes in real time, scientists stand on the brink of a material revolution that could redefine performance standards across numerous sectors. The future of work hardening is not merely constrained to the realm of metals, but may now include a wider array of materials, all optimized for greater strength and utility.

Leave a Reply