In recent years, the need for sustainable methods to synthesize important chemical precursors has gained momentum. A collaborative effort from researchers at Kyushu University has unearthed promising techniques that utilize zeolite materials, particularly Na-ZSM-5, in conjunction with microwave technology for the conversion of biomass into olefins. This discovery offers a glimpse into the future of a more energy-efficient chemical industry, which is vital for producing everything from plastics to pharmaceuticals.

Traditional methods of synthesizing olefins often rely on the reforming of naphtha, a process heavily criticized for high energy consumption and considerable carbon dioxide emissions. This is not just an environmental concern; the economic implications of energy-intensive processes can also weigh heavily on the chemical industry. Compounding these challenges is the need to utilize more sustainable, less polluting feedstocks. Oils derived from cooking waste and microalgae have emerged as alternative raw materials but require efficient conversion techniques.

The use of catalytic cracking, facilitated by zeolite, addresses some of these issues; however, the process remains fraught with challenges. Substantial amounts of energy are necessary to heat materials to temperature ranges between 500 and 600°C. This not only intensifies energy usage but also leads to the unwanted deposition of carbon—referred to as coking—which compromises the longevity and efficiency of catalysts.

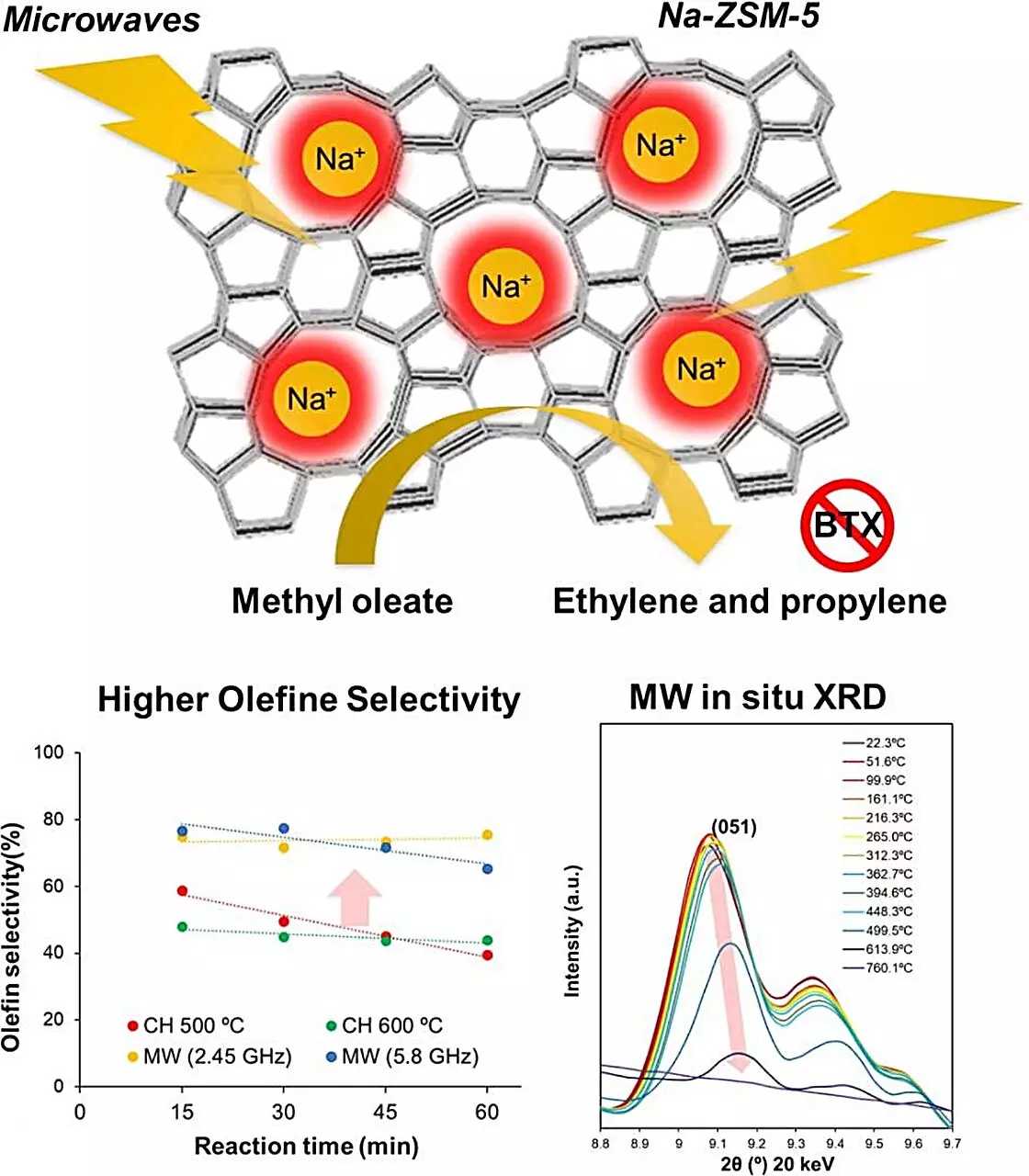

In their groundbreaking study, Associate Professor Shuntaro Tsubaki and his team have demonstrated how microwave technology can radically alter this scenario. Microwaves possess unique heating properties that allow them to penetrate materials directly, selectively transferring energy to solid catalysts like Na-ZSM-5. This results in significant energy savings compared to conventional heating methods, where heat distribution relies on thermal conduction and convection.

Tsubaki points out that the microwave approach not only enhances energy efficiency but also proves highly advantageous in gas-solid catalytic reactions. By forming localized hot spots within the zeolite, microwaves accelerate the conversion processes without the adverse effects typically encountered during standard heating methods.

The researchers embarked on a comprehensive assessment of various zeolite catalysts to identify those capable of optimal microwave heating and catalytic performance. Through a combination of theoretical exploration and experimental validation, Na-ZSM-5 emerged as the clear front-runner. The implications of their findings are substantial.

When subjected to microwave heating, Na-ZSM-5 converted methyl oleate into olefins with an extraordinary efficiency rate. The data revealed that the carbon dioxide output was curtailed to a mere 1.3% of the total reaction—as opposed to standard methods—and there was a complete absence of carbon monoxide production. These impressive metrics were further underscored by a notable fourfold increase in olefin production when Na-ZSM-5 was heated to 500°C via microwaves, compared to conventional heating techniques.

Furthermore, the study highlighted the crucial role played by localized temperature spikes exceeding 1000°C within the zeolite’s crystalline structure, which facilitated the selective production of olefins. Such findings provide deeper insights into how refining heating techniques can lead to not just better yields but also enhanced product quality in chemical synthesis.

The promising outcomes of this research pave the way for transformational advancements in the chemical industry. Tsubaki believes that microwave-assisted catalysis could substantially bolster the electrification of chemical manufacturing. With microwaves capable of being generated from renewable sources, such as solar or wind power, the environmental footprint associated with precursor synthesis could be drastically reduced.

Looking ahead, the research team aims to amplify the efficiency and yield of their microwave-driven catalytic processes while scaling them for wider industrial application. Their vision signals the beginning of what could potentially emerge as a new era in sustainable chemical production.

The insights gleaned from Kyushu University’s research not only offer groundbreaking results but also question long-standing practices within the chemical industry. By integrating innovative technologies like microwave heating into established processes, there exists an uncharted path toward a more environmentally sustainable and economically viable future for chemical manufacturing. The next steps taken by researchers could very well redefine the landscape of industrial chemistry as we know it today.

Leave a Reply