As technology continues to advance, the demand for materials that can withstand extreme environments is becoming increasingly critical. Applications in sectors such as nuclear energy and military operations necessitate materials capable of enduring extreme pressures, high temperatures, and corrosive conditions. In this context, researchers are focused on understanding the behavior of these materials at the atomic level, which is essential for the development of newer, more resilient, and cost-effective solutions. The work undertaken by scientists at Lawrence Livermore National Laboratory (LLNL) provides valuable insights into one such material: zirconium.

In a groundbreaking study published in *Physical Review Letters* and *Physical Review B*, LLNL researchers conducted experiments that revealed the intricate deformation behaviors of single-crystal zirconium when subjected to high pressure. Their findings demonstrate that the material undergoes complex structural changes that defy previous expectations. Traditionally, it was understood that metals primarily deform due to the movement of dislocations along specific crystallographic planes. However, under extreme conditions, zirconium exhibits additional complexities, including crystal structure transformation as pressure increases.

Lead author Saransh Soderlind emphasized the importance of unraveling these microscopic mechanisms to create predictive models on material performance. He stated, “The precise knowledge of the crystallographic planes and the direction a material deforms can allow us to develop models describing the mechanical behavior of metals at extreme levels of compression.” Such models are vital for future applications in high-stress environments.

Innovative Techniques and Findings

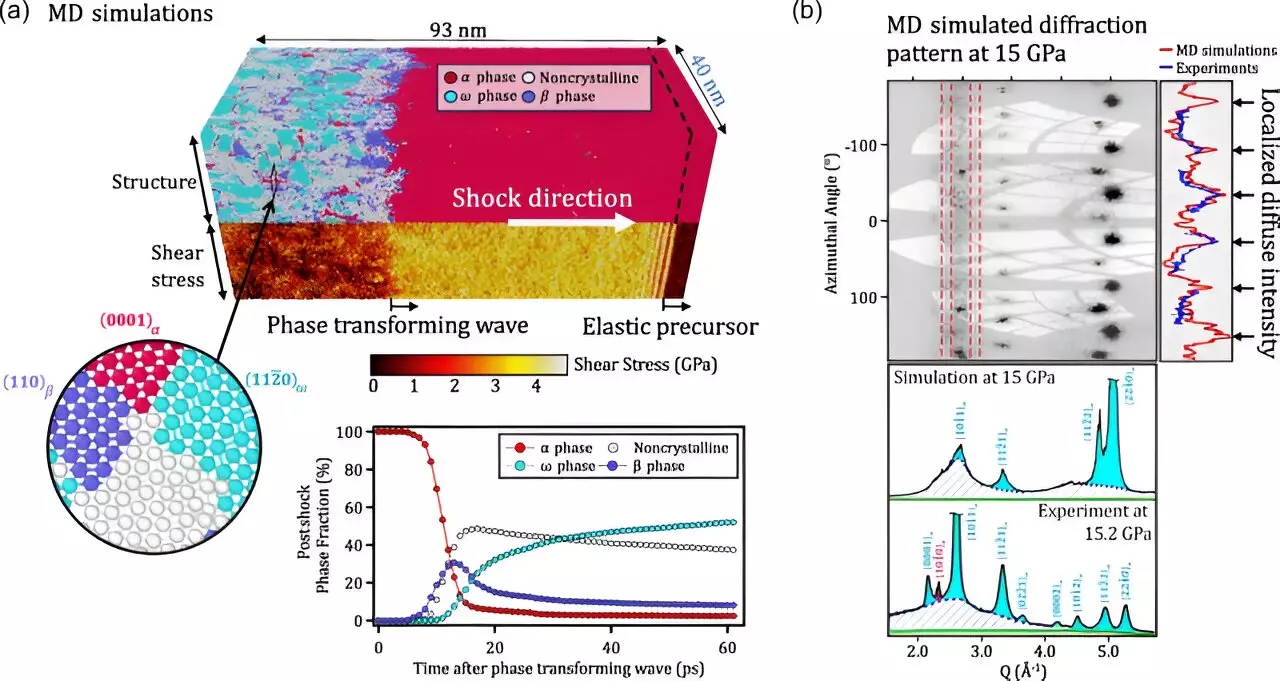

The research utilized cutting-edge techniques such as femtosecond in-situ X-ray diffraction, which enabled the researchers to observe the atomic behavior of zirconium under compressed conditions in nanosecond timeframes. For the first time, they documented atomic disorder and identified multiple pathways for crystal structure transformation when zirconium was compressed—a phenomenon not previously seen in elemental metals.

The study further highlighted the differences observed between single-crystal zirconium and its polycrystalline counterpart, with the latter failing to exhibit the same level of atomic disorder and complexity. This insight suggests that single-crystal zirconium possesses unique characteristics that could have implications for its applications, particularly in the nuclear industry.

The implications of this research extend beyond zirconium alone; the unexpected complexity of atomic movements could indicate similar behaviors in other materials exposed to extreme pressures. Understanding these behaviors will be crucial for developing next-generation materials that are not only more robust and lightweight, but also sustainable.

Zirconium alloys are already integral to the nuclear sector, particularly in fuel rod cladding due to their impressive mechanical strength and low neutron absorption rates. With the newfound understanding of zirconium’s behavior, researchers and industry professionals can enhance the performance of existing materials and potentially create innovative alloys tailored for demanding environments.

The exploration of zirconium’s complex deformation under high pressure opens up new avenues for materials science, emphasizing the need for continued research to unlock further insights into the mechanisms that govern material behavior in extreme conditions.

Leave a Reply