In a world increasingly reliant on technology, the issue of electronic waste (e-waste) has emerged as a significant environmental concern. The recycling of valuable metals from discarded electronics is fraught with ecological pitfalls due to traditional methods’ inefficiencies and environmental hazards. A research team from Rice University, led by the esteemed chemist James Tour, has introduced a groundbreaking approach that not only enhances the recycling process but also substantially mitigates its environmental footprint.

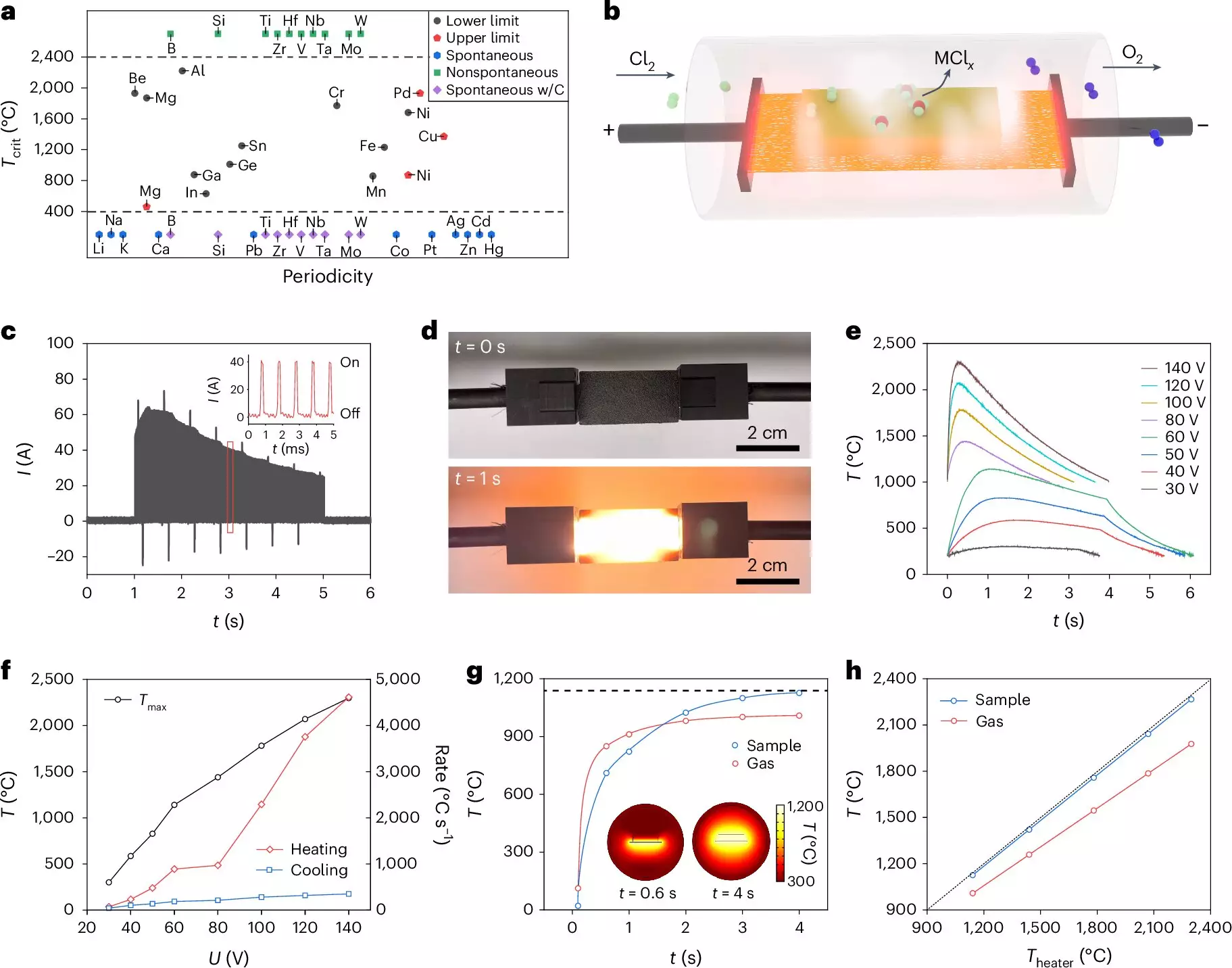

Historically, recycling processes employed in metal recovery such as hydrometallurgy and pyrometallurgy have proven to be energy-intensive and capable of generating harmful waste products. These conventional techniques often rely heavily on the use of acids and large quantities of water. In contrast, the new methodology harnesses flash Joule heating (FJH) in a novel application of chlorination and carbochlorination to recover precious metals from e-waste. This innovative technique eschews water and solvents, thereby cutting down on hazardous waste and ensuring that the recycling process is more sustainable.

Enhancing Metal Recovery

The efficiency of the new method is particularly noteworthy. The research demonstrated that it could achieve a purity rate exceeding 95% for extracted metals, including critical materials like gallium, indium, and tantalum. Furthermore, the yield from these processes surpasses 85%, showcasing a significant advancement over older, less efficient methods. By allowing precise temperature regulation and rapid metal separation, the researchers have crafted a system that promises not only improved metal recovery but also economic viability. As stated by one of the co-authors, Shichen Xu, this innovation directly addresses the growing concern over critical metal shortages in our tech-driven world.

Impacts on the Environment and Industry

This novel approach heralds a transformative shift for the recycling industry. By lowering greenhouse gas emissions and operational costs, it presents a compelling case for sustainable practices that can be adopted on a global scale. As Professor Tour noted, the environmental advantages of this method are dual-fold; it not only diminishes the ecological footprint of metal recovery but also decreases reliance on conventional mining operations known for their destructive environmental impact, including deforestation and waterway contamination. The integration of such sustainable practices can lead to a circular economy wherein valuable materials are continually reused, minimizing waste.

Looking ahead, the team is actively exploring the potential applications of this method for the recovery of lithium and rare Earth elements, which are increasingly critical for a range of emerging technologies. This comprehensive research not only exemplifies the innovative spirit within academic circles but also sheds light on the urgent need for sustainable solutions in the face of an ever-growing e-waste crisis. As the demand for electronic devices continues to escalate, so too does the importance of developing efficient recycling strategies to safeguard our planet and conserve its finite resources.

The research led by James Tour and his team at Rice University represents a decisive step forward in the quest for more sustainable recycling processes. By addressing both the operational and environmental shortcomings inherent in traditional metal recovery methods, this new technique promises not only to enhance metal recovery rates but also to inspire a paradigm shift towards responsible e-waste management. The implications of this work extend far beyond the laboratory; they resonate throughout the recycling industry and underscore the urgent necessity for sustainable practices in an increasingly electronic world.

Leave a Reply