A recent study conducted by the School of Engineering at the Hong Kong University of Science and Technology (HKUST) has introduced a groundbreaking approach to traditional additive manufacturing processes. This method aims to simplify and speed up the production of intricate cellular ceramics, offering new possibilities for applications in various sectors such as energy, electronics, and biomedicine.

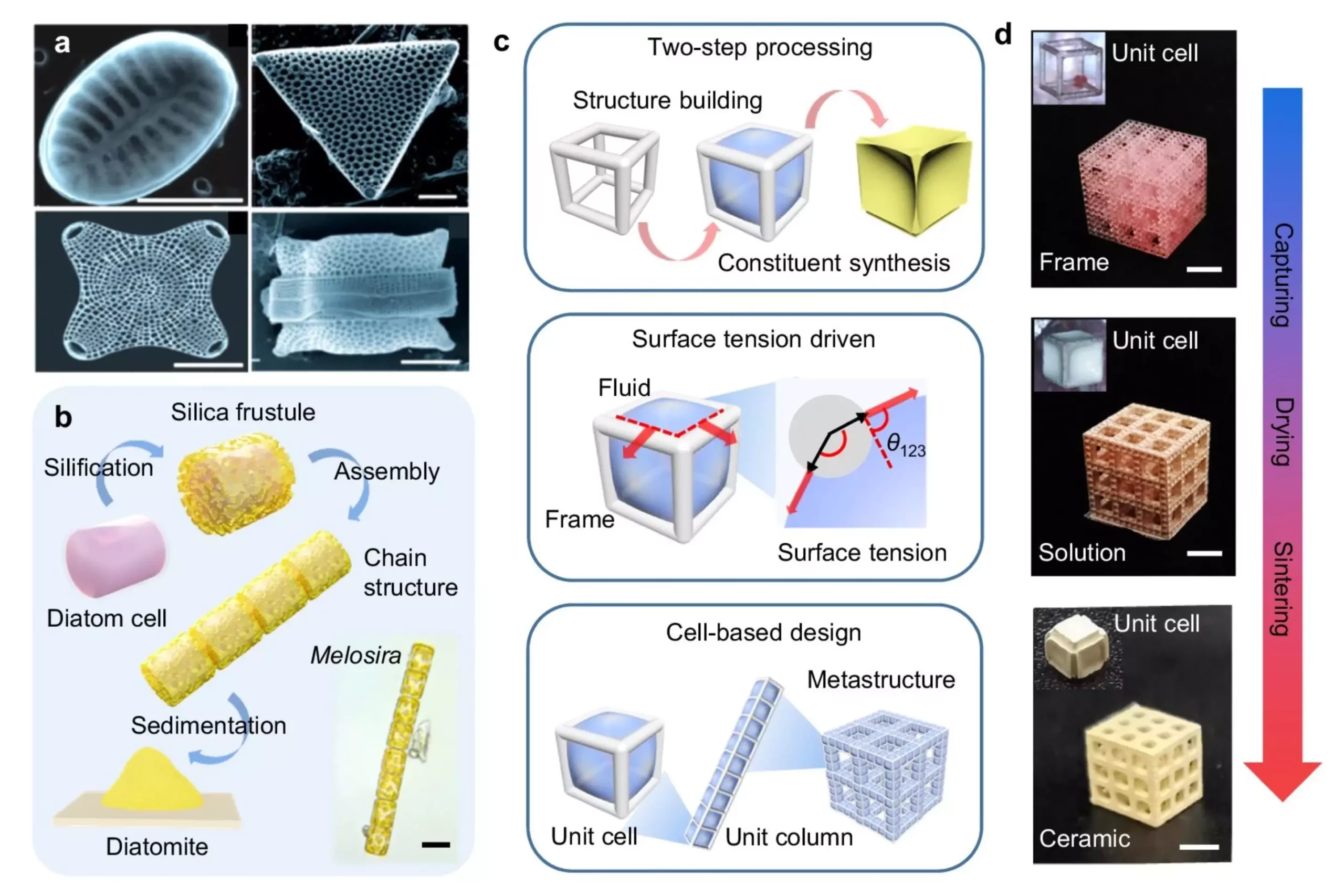

The research team led by Associate Professor Yang Zhengbao has developed a Surface-Tension-Assisted Two-Step (STATS) processing strategy to create cellular ceramics with programmable 3D configurations. This method involves two key steps: preparing cell-based organic lattices using additive manufacturing and then filling them with the required precursor solution.

Controlling the liquid geometry during the manufacturing process was a significant challenge faced by the team. To address this issue, they utilized surface tension as a natural phenomenon to capture the precursor solution within the cellular lattices. This innovative approach allowed them to control the liquid geometry accurately and produce cellular ceramics with high precision.

By separating ingredient synthesis from architecture building, the STATS approach enables the programmable manufacturing of cellular ceramics with diverse cell sizes, geometries, densities, meta-structures, and constituent elements. This high level of programmability makes the method suitable for both structural ceramics like Al2O3 and functional ceramics such as TiO2, BiFeO3, and BaTiO3.

The researchers also evaluated the piezoelectric performance of cellular piezoceramics using the new method. They discovered that the approach could reduce micropores and improve local compactness in sintered cellular ceramics, resulting in a relatively high piezoelectric constant d33 (~200 pC N-1) even with a high overall porosity (>90%). This advancement opens up new possibilities for the manufacturing of cellular piezoceramics with superior performance.

Professor Yang Zhengbao drew inspiration from diatoms, single-celled algae known for their intricate silica frustules. These organisms undergo a genetically programmed biomineralization process to create precise and complex structures with a variety of morphologies, shapes, geometries, and pore distributions. The novel method developed by the research team mimics the biomineralization process of diatoms to achieve programmable ceramic architectures.

The innovative method developed by the HKUST research team offers a promising solution to the challenges faced in traditional manufacturing processes. By leveraging surface tension and separating ingredient synthesis from architecture building, the STATS approach enables the rapid and precise production of cellular ceramics with diverse configurations and enhanced performance characteristics. This breakthrough has the potential to revolutionize the design and processing of ceramic materials, opening up new possibilities for a wide range of applications in various industries.

Leave a Reply